Detail

SILIKE Si-TPV 2250 Series is a dynamic vulcanized thermoplastic silicone-based elastomer designed to enhance EVA foaming materials. The Si-TPV 2250 Series is produced using a specialized technology that ensures silicone rubber is dispersed evenly in EVA as 1–3 micron particles. This unique modifier for EVA foaming material combines the strength, toughness, and abrasion resistance of thermoplastic elastomers with the desirable properties of silicone, including softness, a silky feel, UV resistance, and chemical resistance. It can be recycled and reused in traditional manufacturing processes.

Si-TPV 2250 Series Eco-Friendly Soft Touch Material materials are highly compatible with ethylene-vinyl acetate (EVA) and serve as an innovative silicone modifier for EVA Foaming, Solutions for improving EVA foam materials in applications such as shoe soles, sanitary products, sports leisure products, floor mats, yoga mats, and more.

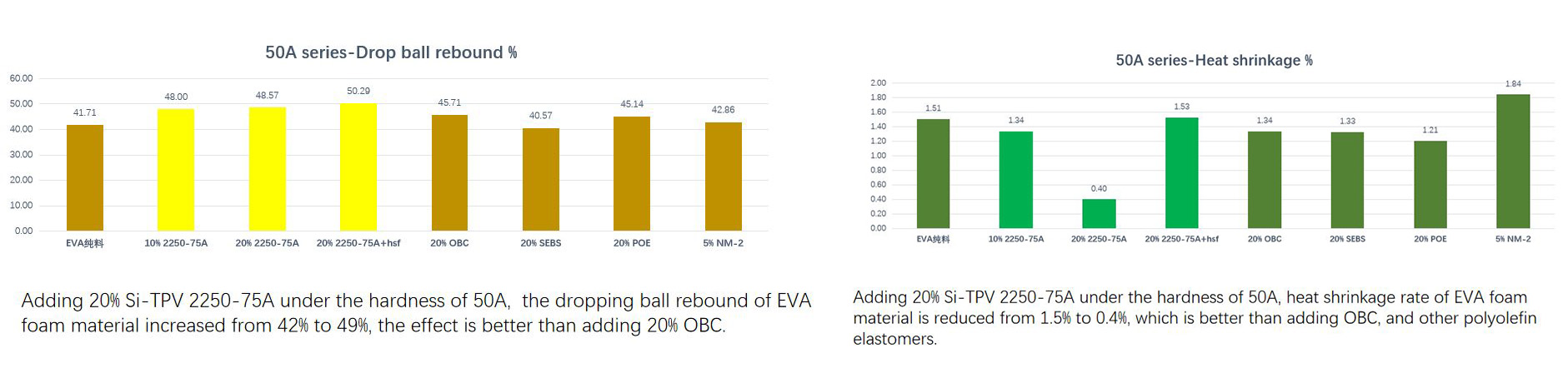

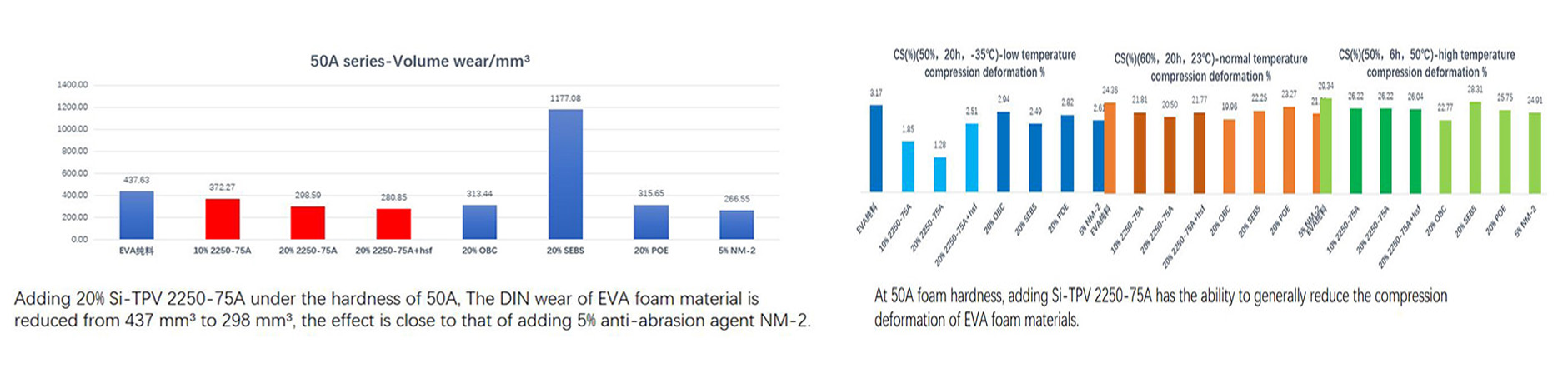

Compared with OBC and POE, Highlight reduces the compression set and heat shrinkage rate of EVA foam materials, improves the elasticity and softness of EVA foaming, improves the anti-slip and anti-abrasion resistance, and the DIN wear is reduced from 580 mm3 to 179 mm3 and improves the color saturation of EVA foam materials.

Which have proven to be effective Flexible Soft Eva Foam Material Solutions.

Key Benefits

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

Si-TPV Modifier For EVA Foaming Case studies

The Si-TPV 2250 Series features long-term skin-friendly soft touch, good stain resistance, and does not require the addition of plasticizers or softeners. It also prevents precipitation after extended use. As a highly compatible and innovative soft Eva foam modifier, it is particularly well-suited for the preparation of super-light, highly elastic, eco-friendly EVA foaming materials.

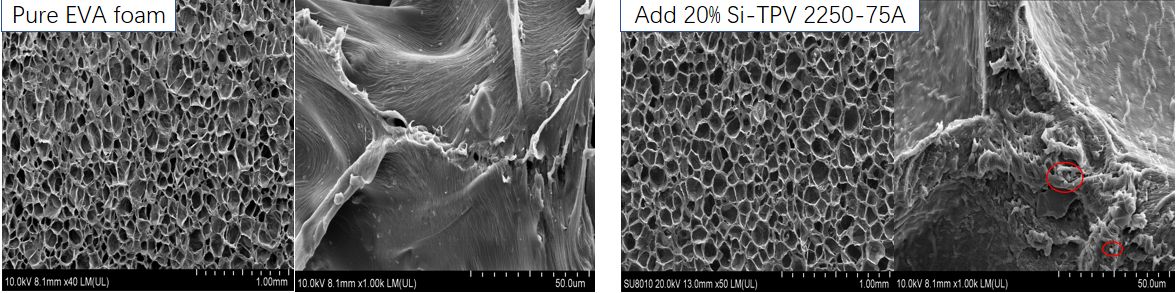

After adding Si-TPV 2250-75A, the bubble cell density of EVA foam gets slightly reduce, bubble wall thickening, and Si-TPV is dispersed in the bubble wall, the bubble wall becomes rough.

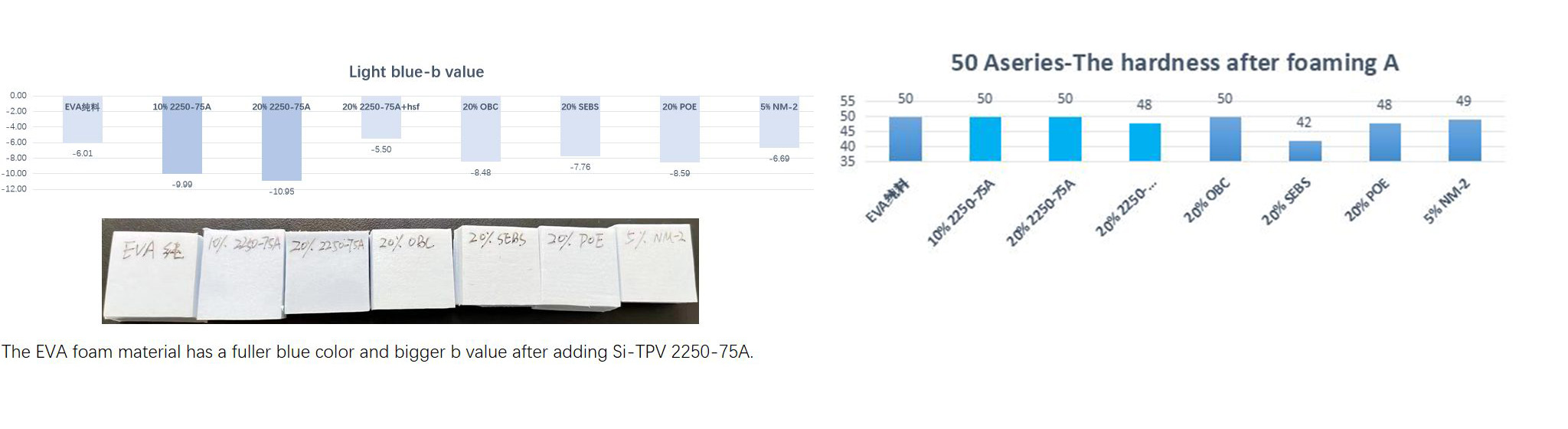

Comparison of Si-TPV2250-75A and polyolefin elastomer addition effects in EVA foam

Application

Novel green environment-friendly Si-TPV modifier empowering the EVA foaming material that reshaped various daily life and business activities products industries. such as footwear, sanitary products, bathtub pillows, sports leisure products, floor/yoga mats, toys, packaging, medical devices, protective equipment, water non-slip products, and photovoltaic panels...

If you're focused on solutions for supercritical foaming, we’re not sure if it’s for you, but this Si-TPV modifier reshaping chemical foaming technology. For EVA foaming manufacturers can be an alternative way to create lightweight and flexible products with precise dimensions.

Solutions:

Enhancing EVA Foams: Solving EVA Foam Challenges with Si-TPV Modifiers

1. Introduction to EVA Foam Materials

EVA foam materials are a type of closed-cell foam produced from a blend of ethylene and vinyl acetate copolymers, with polyethylene and various foaming agents and catalysts introduced during manufacturing. Renowned for its superior cushioning, shock absorption, and water resistance, EVA foam features a lightweight yet durable structure that offers excellent thermal insulation. Its remarkable properties make EVA foam a versatile material, widely used in both everyday products and specialized applications across various industries, such as shoe soles, soft foam mats, yoga blocks, swimming kickboards, floor underlay, and so on.

2. What Are the Limitations of Traditional EVA Foams?

Many people think that EVA foam material is the perfect combination of a hard shell and soft shell, However, the use of EVA foamed materials is limited to a certain extent because of its poor aging resistance, flexure resistance, elasticity, and abrasion resistance. The rise of ETPU in recent years and the comparison of samples also make EVA foamed shoes must have lower hardness, higher rebound, low compression deformation, and other new properties.

Additionally, Environmental and Health Challenges of EVA Foam Production.

EVA foamed products provided in the market at present are prepared by a chemical foaming method and are mainly used for products such as shoe materials, ground mats, and the like which are in direct contact with human bodies. However, the EVA foaming material prepared by the method and the process has various environmental protection and health problems, and particularly, harmful substances (particularly formamide) are continuously separated from the interior of the product for a long time.