Si-TPV series product

Si-TPV series products are launched dynamic vulcanizate thermoplastic Silicone-based elastomers by SILIKE,

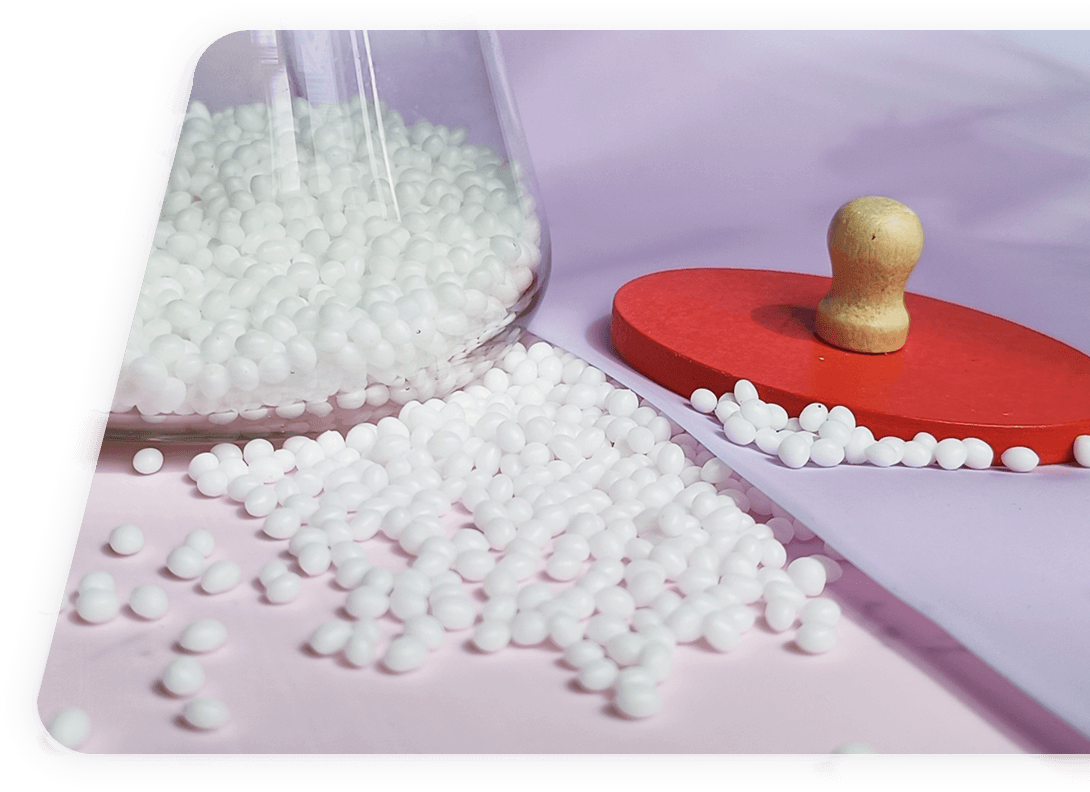

Si-TPV is a cutting-edge dynamic vulcanizate thermoplastic silicone-based elastomer, also known as silicone thermoplastic elastomer, developed by Chengdu SILIKE Technology Co., Ltd. It contains fully vulcanized silicone rubber particles, ranging from 1-3um, evenly dispersed in a thermoplastic resin to form a special island structure. In this structure, the thermoplastic resin serves as the continuous phase, while the silicone rubber acts as the dispersed phase. Si-TPV demonstrates superior performance compared to ordinary thermoplastic vulcanized rubber (TPV) and is often referred to as ‘Super TPV.'

It is currently one of the world's very unique and innovative environmentally friendly materials, and can bring downstream customers or end-product manufacturers benefits such as ultimate skin-friendly touch, wear resistance, scratch resistance, and other competitive advantages.

Si-TPV combination of properties and benefits of both the strength, toughness, and abrasion resistance of any thermoplastic elastomer with the desirable properties of fully cross-linked silicone rubber: softness, silky feel, resistance to UV light and chemicals, and outstanding colorability, but unlike traditional thermoplastic vulcanizates, they can be recycled and reused in your manufacturing processes.

Our Si-TPV features the following properties

≫ Long-term silky skin-friendly touch, does not require additional processing or coating steps;

≫ Reduce dust adsorption, non-tacky feel that resists dirt, no plasticizer and softening oil, no precipitation, odorless;

≫ Freedom custom colored and deliver long-lasting colorfastness, even with exposure to sweat, oil, UV light, and abrasion;

≫ Self-adhered to hard plastics to enable unique over-molding options, easy bonding to polycarbonate, ABS, PC/ABS, TPU, PA6, and similar polar substrates, without adhesives, over-molding capability;

≫ Can be manufactured using standard thermoplastic manufacturing processes, by injection molding/extrusion. Suitable for co-extrusion or two-color injection molding. Precisely matched to your specification and are available with matte or gloss finishes;

≫ Secondary processing can carve all kinds of patterns, and do screen printing, pad printing, spray painting.

Application

All Si-TPV elastomers provide unique green, safety friendly soft hand touch feeling in hardness ranging from Shore A 25 to 90, good resilience, and softer than general thermoplastic elastomers, making them the ideal eco-friendly material to enhance stain resistance, comfort, and fit of 3C electronics, wearable devices, sports gear, mother baby products, adult products, toys, apparel, accessories cases, and footwear, and other consumer products.

In addition, Si-TPV as a modifier for TPE and TPU, which could be added to TPE and TPU compounds to improve the smoothness and touch feeling, and reduce the hardness with no negative effect on mechanical properties, aging resistance, yellow resistance, and stain resistance.