Detail

Environmental problems are becoming more and more prominent as economic development, and achieving green chemistry is an urgent task nowadays. Supercritical foam technology is a revolutionary new technology, the foaming agents used in supercritical foaming technology are usually supercritical carbon dioxide (ScCO2) and supercritical nitrogen (ScN2), both of which are used without environmental burden.EVA (Ethylene Vinyl Acetate) foam is a common lightweight, soft, and durable plastic material that has been a stalwart in various industries due to its versatility, flexibility, and cost-effectiveness.

Key Benefits

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

EVA foaming Guide

Si-TPV 2250 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for Super light high elastic eco-friendly EVA foaming material preparation.

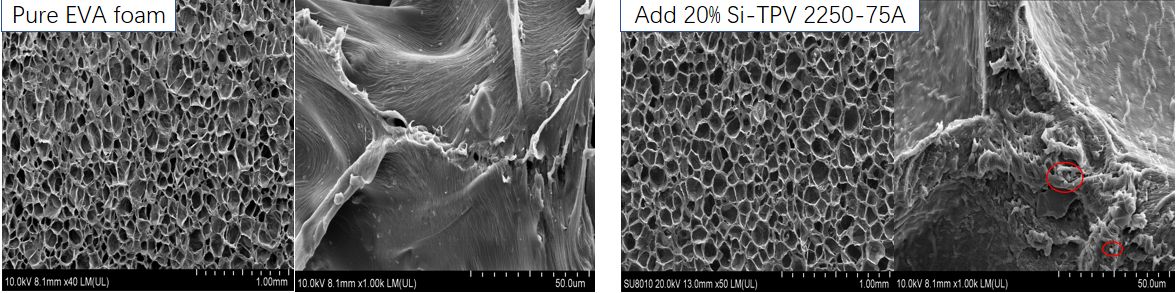

After adding Si-TPV 2250-75A, the bubble cell density of EVA foam gets slightly reduce, bubble wall thickening, and Si-TPV is dispersed in the bubble wall, the bubble wall becomes rough.

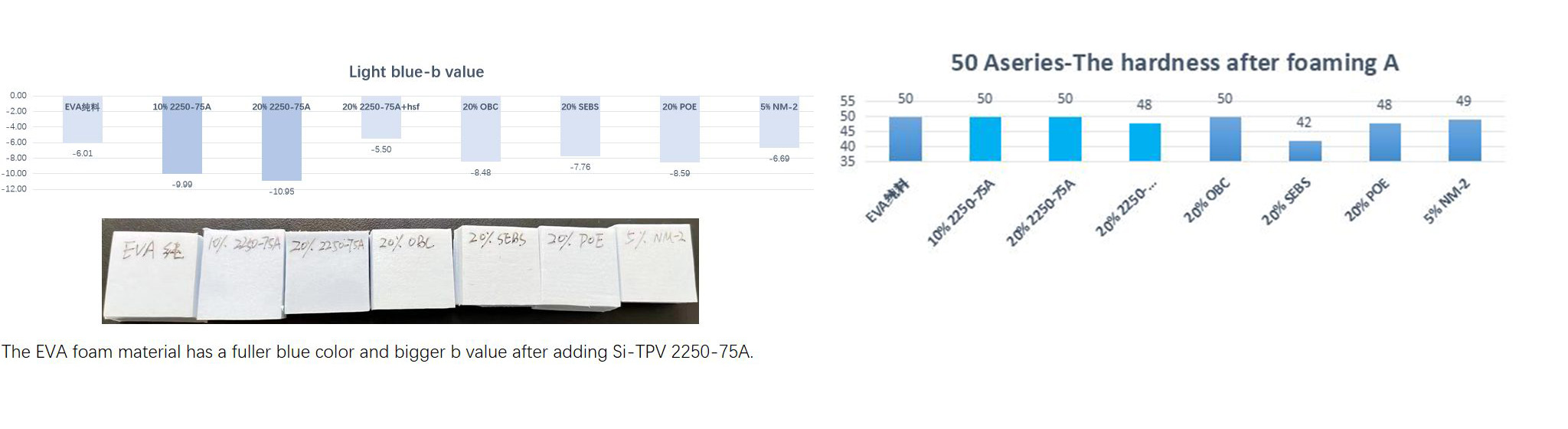

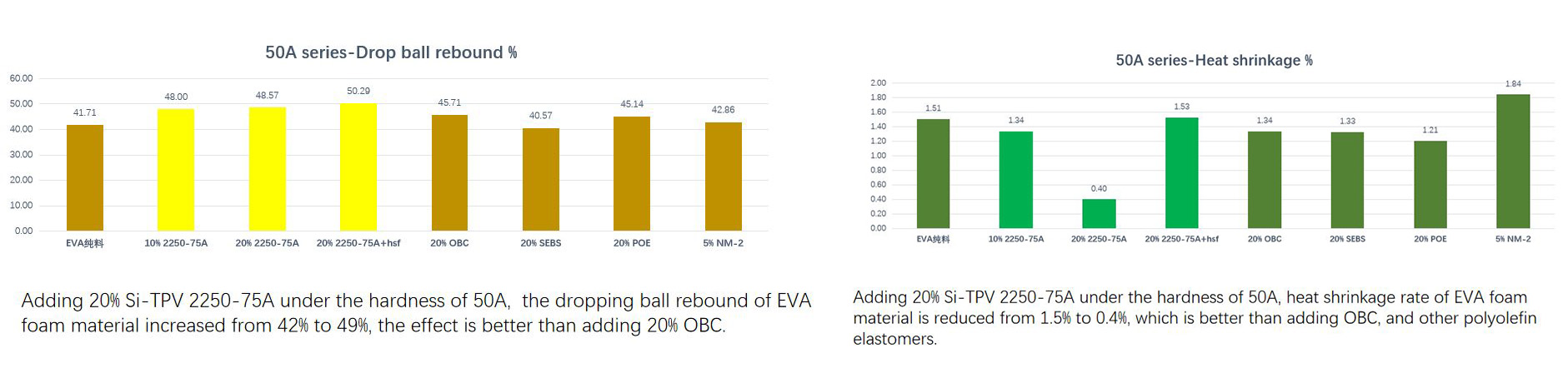

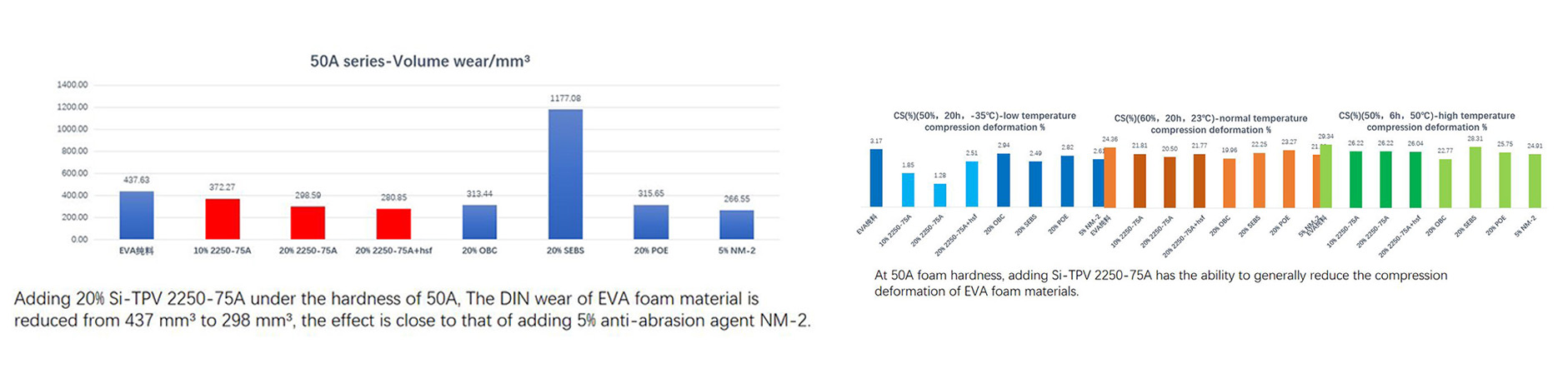

Comparison of Si-TPV2250-75A and polyolefin elastomer addition effects in EVA foam

Application

Novel green environment-friendly Si-TPV modifier empowering the EVA foaming material that reshaped various daily life and business activities products industries. such as footwear, sanitary product, sports leisure products, floor/yoga mats, toys, packaging, medical devices, protective equipment, water non-slip products, and photovoltaic panels...

For example, in the production of footwear products, the common foam material for soles, insoles, and insole liners is EVA material, which plays a role in effectively supporting and cushioning the feet and improving wearing comfort. In addition, EVA foam is also widely used in the packaging industry. Because of its lightweight and has good cushioning and protective properties, EVA foam is often used to make boxes, packaging cushions, etc., to protect the product from vibration and extrusion damage during transportation. Of course, EVA foam is also often used in the manufacture of sports equipment. For example, in fitness equipment, yoga mats made of EVA foam materials have better anti-slip, waterproof and comfortable performance, providing yoga enthusiasts with a safe and comfortable workout environment. Overall, EVA foam is a very versatile material. Its lightweight, soft and durable properties make it an important application in footwear products, packaging, sports equipment and other fields. However, the environmental impact of traditional EVA foam production has raised concerns, prompting a search for sustainable alternatives.