Si-TPV Soft EVA Foam Modifier (also known as Silicone For EVA Foaming, Modifier For EVA Foaming Shoes), provides breakthrough Soft EVA Foam Modifier Solutions for EVA shoe sole foaming, and a Solutions For Supercritical Foaming, using Chemical Foaming Technology For Lightweight Eva Foam, effectively improves abrasion resistance, reduces heat shrinkage, enhances rebound and compression set, and improves color saturation and uniformity. Its unique properties make it ideal for producing vibrant and durable soles that meet the demands of modern footwear applications.

EVA is the fourth largest polymer in the ethylene family after HDPE, LDPE and LLDPE. It is much less expensive than traditional materials. Many consider EVA foam to be the perfect combination of hard and soft shells, retaining the advantages of soft and hard foams while discarding the disadvantages. What’s more, the flexibility inherent in the material’s design and manufacturing capabilities is a major factor in why some of the world’s leading companies and brands turn to EVA foam when they need a high-quality, low-cost manufacturing material.

EVA foam takes care of our daily lives and business activities, and has spawned end-user preference for it. With strong demand for durable plastic products in footwear, pharmaceuticals, photovoltaic panels, sports and leisure goods, toys, flooring/yoga mats, packaging, medical devices, protective gear, and water sports goods, the EVA foam segment continues to see new growth.

EVA foaming generally speaking, there are four processes:

Traditional flat plate large foam: now small factories generally use this, the cost of machinery and equipment is relatively low. This process is done out of the plate, and then through the process of punching, grinding and other processes into products.

In-mold small foam: this process is mainly used in shoes, sports shoes to do the first foam of the secondary midsole. According to the formula to practice good material granulation, weighing into the open mold, foaming out is the general appearance of the shoes. The difficulty of this process is the symmetry of the mold and formula, otherwise it is difficult to control the multiplier and hardness at the same time.

Injection: this process is the mainstream of the future, a process is done out of the product, but the mold precision is higher.

Supercritical foaming: The molecular chain of EVA is linear, so it is usually necessary to add cross-linking agent in the foaming process to lock the gas through the cross-linking structure. Therefore, the supercritical foaming of EVA needs to solve the problem of how to lock the gas.

Application

As an innovative modifier for EVA foam materials, Si-TPV facilitates the production of comfortable and durable EVA foam-related products, such as athletic shoe midsoles.

EVA foaming Guide

Si-TPV 2250 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for Super light high elastic eco-friendly EVA foaming material preparation.

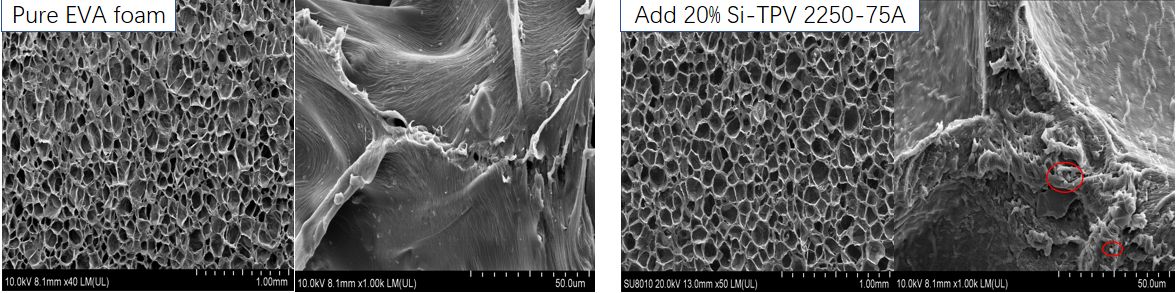

After adding Si-TPV 2250-75A, the bubble cell density of EVA foam gets slightly reduce, bubble wall thickening, and Si-TPV is dispersed in the bubble wall, the bubble wall becomes rough.

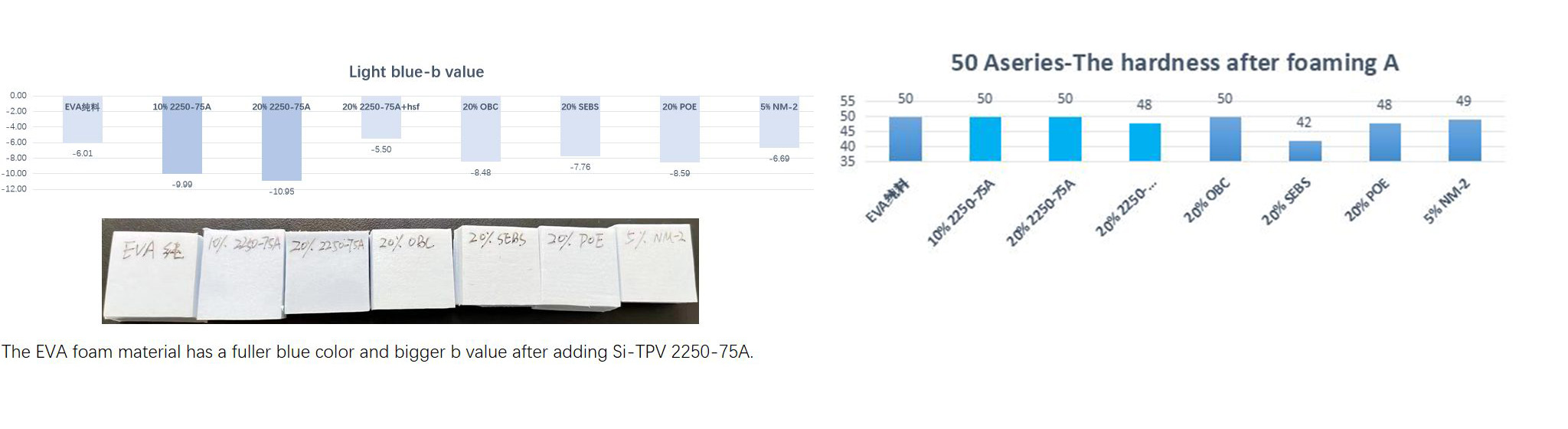

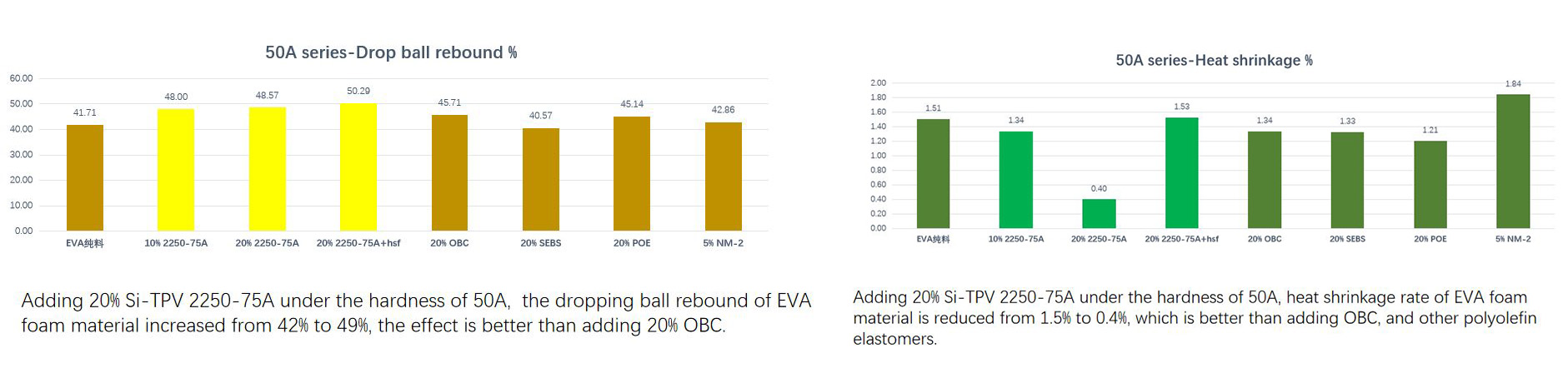

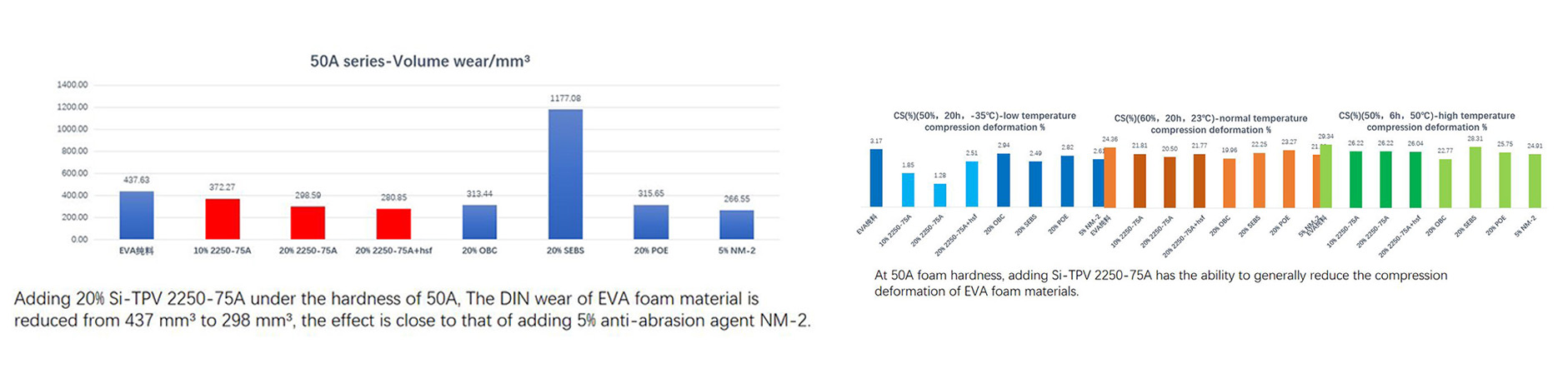

Comparison of Si-TPV2250-75A and polyolefin elastomer addition effects in EVA foam

Key Benefits

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.