Detail

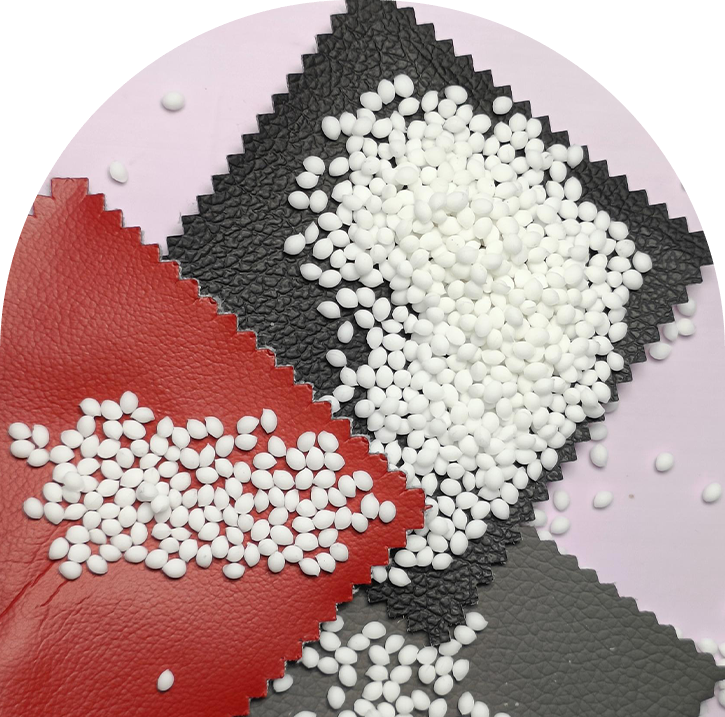

Silicone Si-TPV, a combination of silicone rubber and TPU dual characteristics of the phone case material, it has a high efficiency, high performance, high cost-effective three high advantages, so that this material in the pursuit of individuality, functionality and efficiency in the context of the times, cell phone case manufacturers cannot miss a choice.

Key Benefits

Durability Sustainability

-

Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations

Si-TPV Overmolding Solutions

|

Overmolding recommendations |

||

|

Substrate Material |

Overmold Grades |

Typical Applications |

|

Polypropylene (PP) |

Sport Grips, Leisure Handles,Wearable Devices Knobs Personal Care- Toothbrushes, Razors, Pens, Power & Hand Tool Handles, Grips, Caster Wheels,Toys |

|

|

Polyethylene (PE) |

Gym Gear, Eyewear, Toothbrush Handles,Cosmetic Packaging |

|

|

Polycarbonate (PC) |

Sporting Goods, Wearable Wristbands, Handheld Electronics, Business Equipment Housings, Healthcare Devices, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Acrylonitrile Butadiene Styrene (ABS) |

Sports & Leisure equipment, Wearable Devices, Housewares, Toys, Portable Electronics, Grips, Handles, Knobs |

|

|

PC/ABS |

Sports Gear, Outdoor Equipment,Housewares, Toys, Portable Electronics, Grips, Handles, Knobs, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Standard and Modified Nylon 6, Nylon 6/6, Nylon 6,6,6 PA |

Fitness Goods, Protective Gear, Outdoor Hiking Trekking Equipments, Eyewear, Toothbrush Handles, Hardware, Lawn and Garden Tools, Power Tools |

|

Overmolding Techniques & Adhesion Requirements

SILIKE Si-TPVs Overmolding can adhere to other materials through injection molding. suitable for insert molding and or multiple material molding. Multiple material molding is otherwise known as Multi-shot injection molding, Two-Shot Molding, or 2K molding.

SI-TPVs have excellent adhesion to a variety of thermoplastics, from polypropylene and polyethylene to all kinds of engineering plastics.

When selecting an Si-TPV for an over-molding application, the substrate type should be considered. Not all Si-TPVs will bond to all types of substrates.

For more information regarding specific over-molding Si-TPVs and their corresponding substrate materials, please feel contact us.

Application

Si-TPVs provide a uniquely smooth feel in hardness ranging from Shore A 35 to 90A making them the ideal material to enhance the aesthetics, comfort, and fit of 3C Electronic Products, including hand-held electronics, wearable devices(from phone cases, wristbands, brackets, watch bands, earbuds, necklaces, and AR/VR to silky-smooth parts...), as well as improve scratch resistance and abrasion resistance for the housings, buttons, battery covers and accessory cases of portable devices, consumer electronics, household products, and homewares or other appliances.

1. Skin-friendly and dirt-resistant, visual and tactile double sublimation

Silicone phone case by its own material limitations, there is a general astringent problem in the touch, need to spray or UV curing to improve the feel. In addition, dirt resistance is a big hurdle that silicone phone cases can not cross, silicone has a certain adsorption capacity, when there are stolen goods adsorbed in the phone case when it becomes difficult to clean, such as: ink, paint and other dirt, and easy to get stuck in the cracks of the dust, so as to affect the aesthetics of the phone. In contrast, Si-TPV has excellent skin-friendly touch, no need for secondary treatment, and excellent performance in terms of dirt resistance, which can do double sublimation from the visual and tactile.

2. Dry and wear-resistant, effectively extending the service life

Many silicone cell phone cases are sticky and worn out during long-term use. In this case, Si-TPV has non-stick, wear-resistant properties that make it better able to maintain a long-lasting smooth feel, extend the life of the case, and play an effective role in protecting the phone.

3. Optimize processing to meet personalized needs

In the pursuit of personalization, cell phone cases have become colorful from single shape and color. Silicone phone cases can’t change shape in the process, and some can only complete a single color co-extrusion or injection molding, and can’t meet the personalized market demand. Si-TPV can be co-extruded with many thermoplastic engineering plastics such as PC, ABS, PVC, etc., or two-color injection molding, the product shape is rich, it is a good choice for personalized cell phone case materials. In addition, Si-TPV has excellent performance in logo printing, effectively solving the problem of easy to fall off the logo of cell phone cases.