Detail

A good insulation cup not only can effectively maintain the temperature of the beverage, but also provide excellent sealing performance. Of course, it is even more critical that the sealing part of the insulation cup is made of contact-safe materials.

A good thermos not only needs to be versatile, but it also needs to meet the relevant food contact grade safety regulations.

Key Benefits

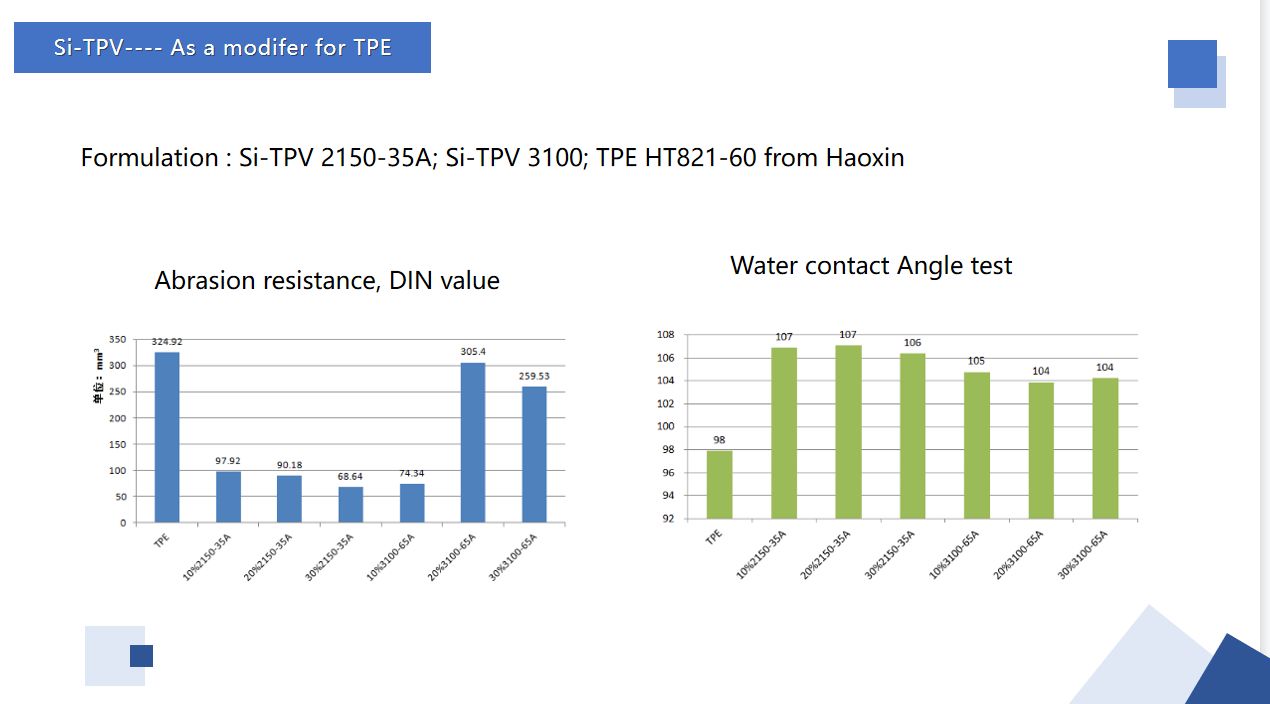

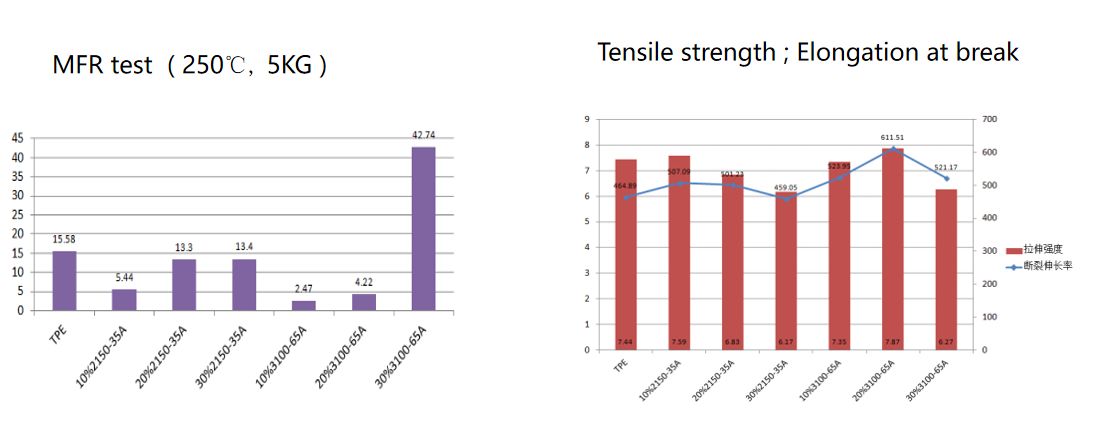

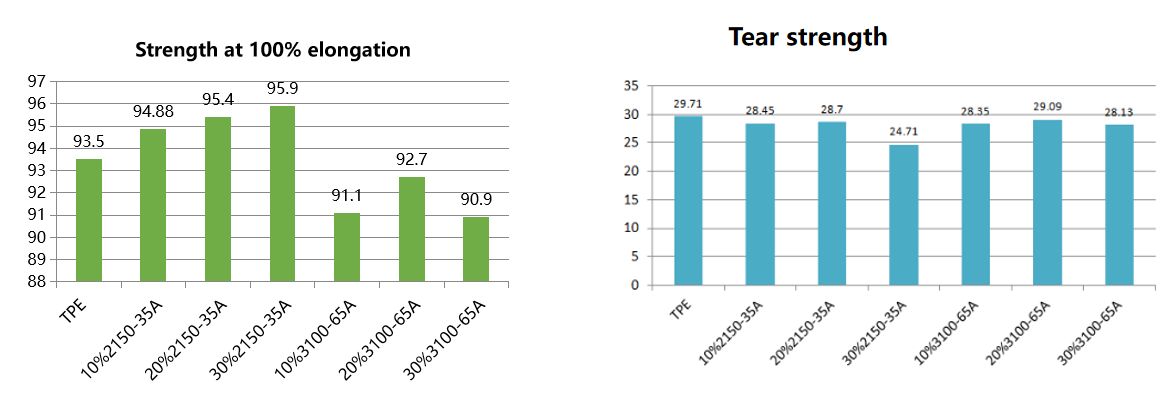

- In TPE

- 1. Abrasion resistance

- 2. Stain resistance with a smaller water contact angle

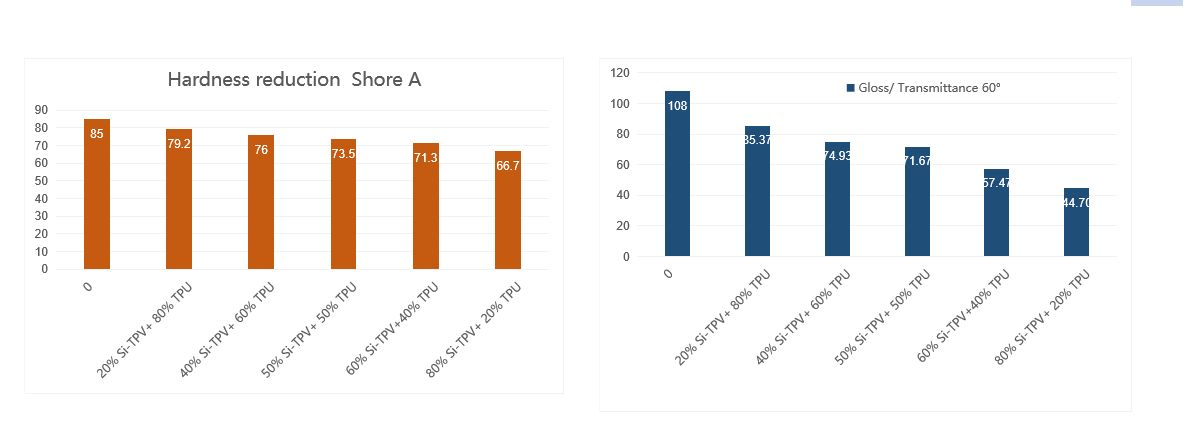

- 3. Reduce hardness

- 4. Almost no influence on mechanical properties with our Si-TPV 2150 series

- 5. Excellent haptics, dry silky touch, no blooming after long-term use

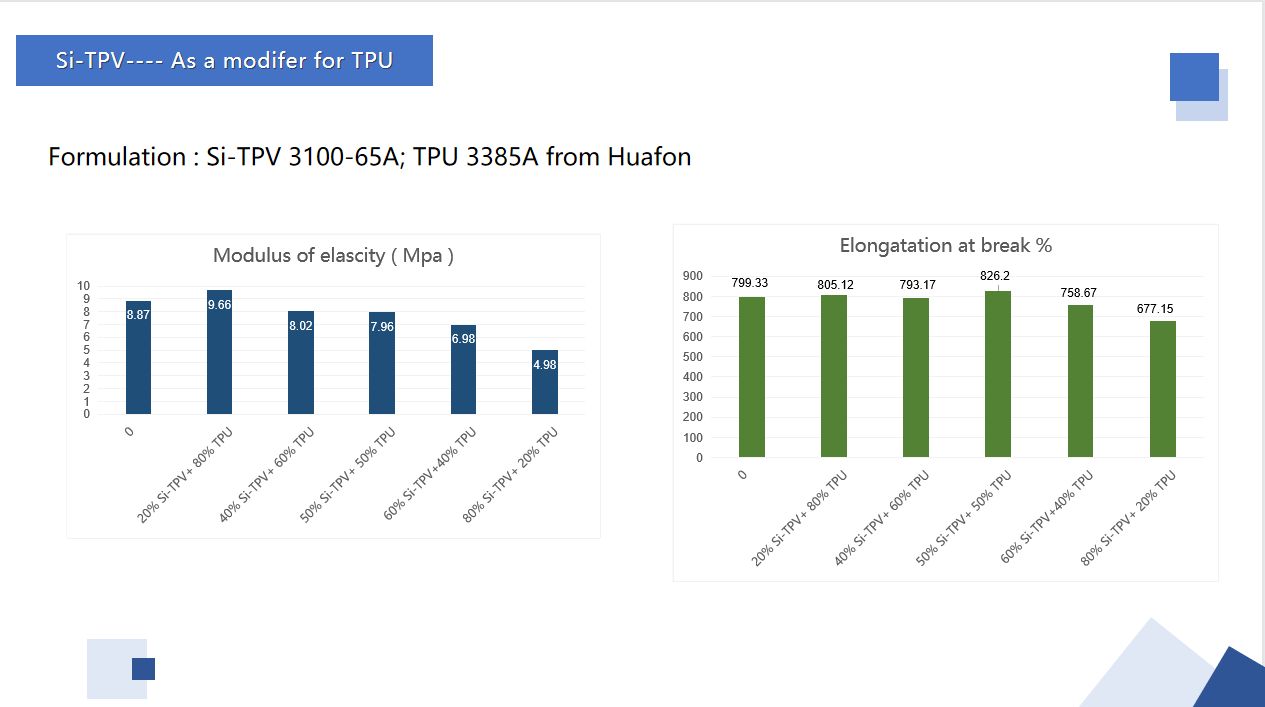

- In TPU

- 1. Hardness reduction

- 2. Excellent haptics, dry silky touch, no blooming after long-term use

- 3. Provide the final TPU product with a matt effect surface

- 4. Slightly affect Mechanical properties if the addition of over 20%

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations

Si-TPV as a modifer & process additive Guide

Si-TPV 2150 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for silky pleasant feel thermoplastic elastomers preparation.

Application

Not only can it be applied in the field of thermal insulation cups, but it is also widely used in many fields of food contact, such as cup seals, lunch box seals, etc., which significantly improves the product performance and use experience. In the future, Si-TPV silicone-based thermoplastic elastomers will gradually penetrate into all aspects of our daily life and work, creating a more comfortable and safer life for us. Si-TPV silicone-based thermoplastic elastomers will also continue to innovate themselves in order to create a better life, and build a more complete and richer product system.

SILIKE has developed a new plasticizer-free elastomeric material(Eco-friendly soft touch material) – Si-TPV silicone-based thermoplastic elastomers – for this application. This series of Elastomeric Materials have been tested by the US FDA and China’s food safety monitoring agency for food contact grade safety, ensuring that the products are free of BPA, heavy metals, plasticizers and other harmful substances to the human body.

Compared with TPR materials, Si-TPV silicone-based thermoplastic elastomer materials are good overmolding materials with excellent soft-touch overmolding effect and processing fluidity.Compression permanent deformation is small, with excellent resilience, excellent sealing effect, as well as good abrasion resistance, can effectively prevent heat loss, to ensure that the beverage temperature is maintained for a long time, to extend the service life of the insulation cup, and at the same time will not produce harmful substances, to protect the health of the insulation cup seals, very suitable for insulation cup sealing applications.