Detail

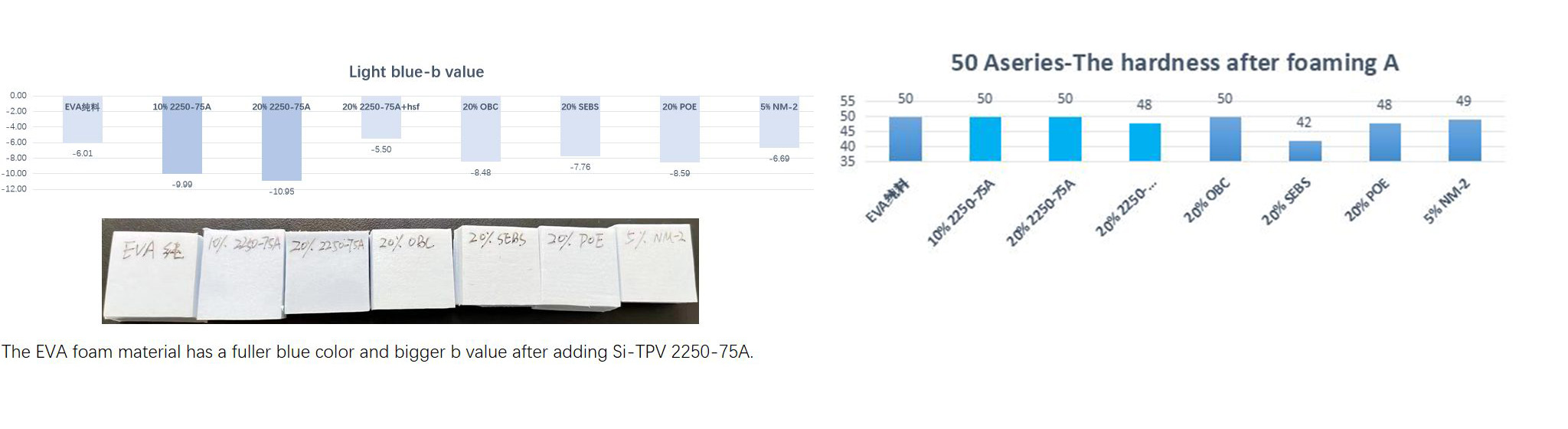

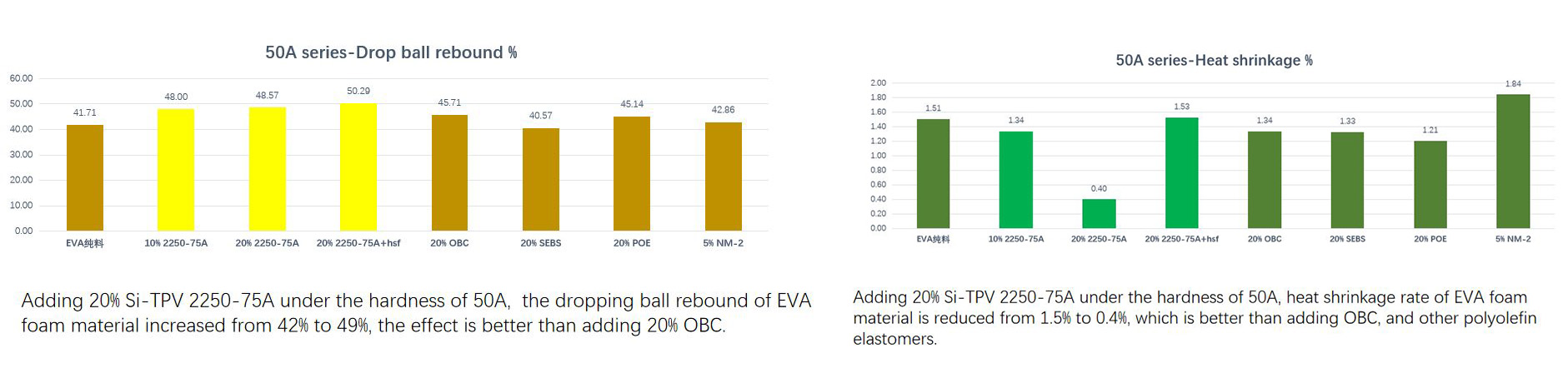

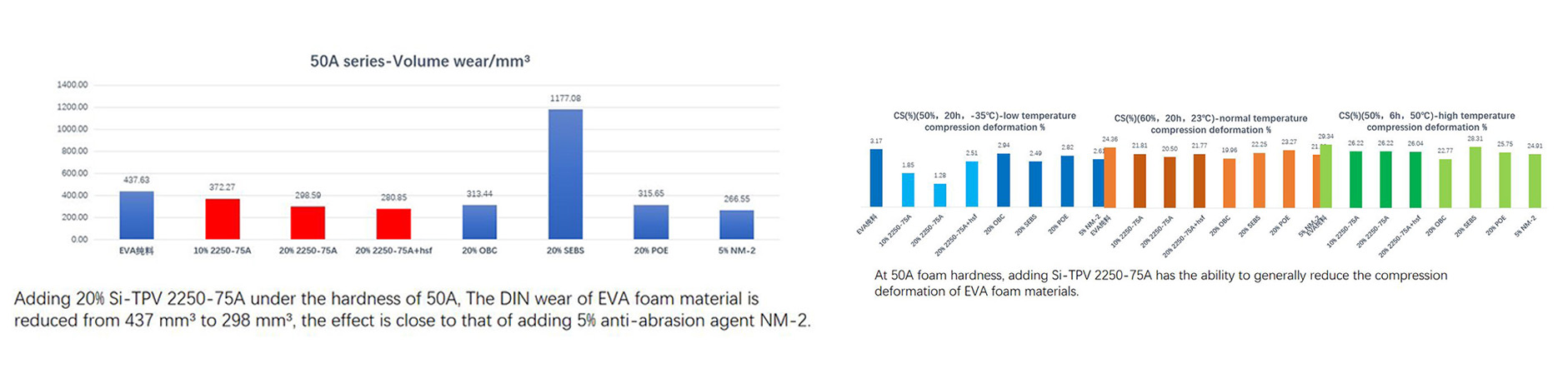

Si-TPV dynamic vulcanizate thermoplastic silicone-based elastomer is an innovative Easy clean EVA foam modifier. it can be used as Modifier EVA foam for seating, Modifier It can be used as Modifier EVA foam for seating, Modifier EVA foam for protective equipment, Modifier EVA foam for construction toys, Modifier EVA foam for shin guards, and it can also facilitate the upgrade of Eva foaming running shoes technology upgrading. It has the advantages of reducing the thermal shrinkage of EVA foam, improving the resilience and abrasion resistance, improving the compression deformation of the material, and promoting the bubble holes to be more uniform and dense.

Key Benefits

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

EVA foaming Guide

Si-TPV 2250 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for Super light high elastic eco-friendly EVA foaming material preparation.

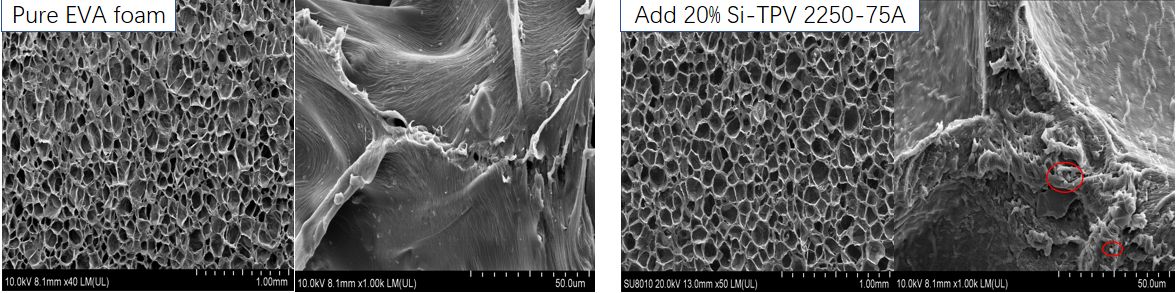

After adding Si-TPV 2250-75A, the bubble cell density of EVA foam gets slightly reduce, bubble wall thickening, and Si-TPV is dispersed in the bubble wall, the bubble wall becomes rough.

Comparison of Si-TPV2250-75A and polyolefin elastomer addition effects in EVA foam

Application

By incorporating Si-TPV modifiers into your manufacturing processes, businesses can produce EVA foam materials endowed with enhanced resilience, durability, and comfort, catering to diverse applications, including shoe soles, sanitary products, sports leisure items, floor/yoga mats, and more.

Unlike its semi-crystalline counterpart, polyethylene, the introduction of VA monomers disrupts the formation of crystals in the polymer chain, resulting in reduced crystallinity. As the VA content increases, EVA becomes progressively amorphous, leading to changes in its physical and mechanical properties. While parameters like elongation at break, glass transition temperature, and density increase with higher VA content, others such as tensile strength, modulus, hardness, and melting temperature decrease. However, despite its enhanced elasticity, EVA may exhibit deficiencies in tear strength, wear resistance, and compression set, particularly in applications requiring robustness.