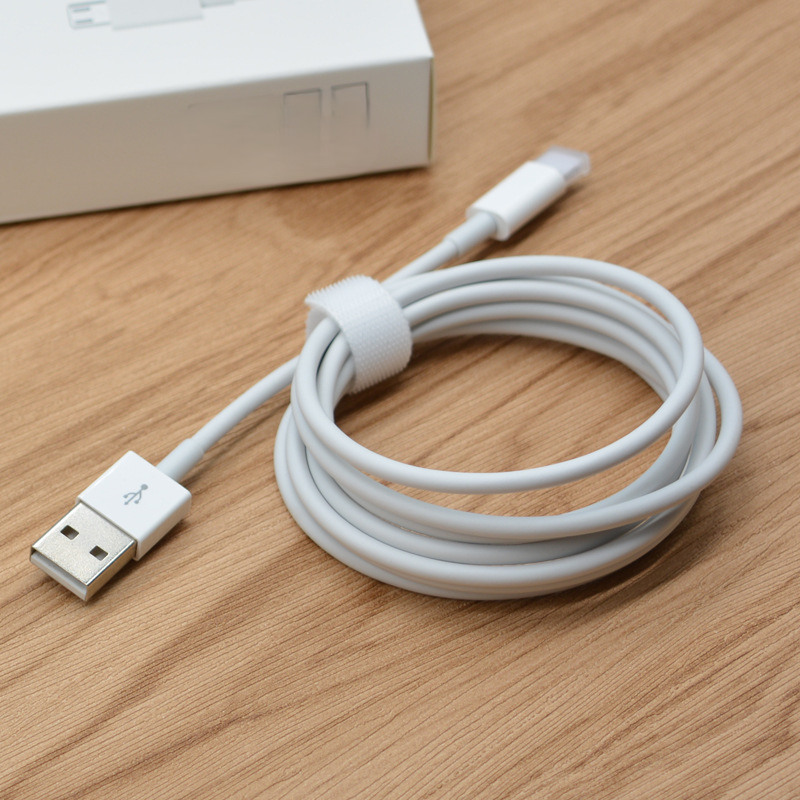

In the ever-evolving world of consumer electronics, soft-touch materials have become a key factor in enhancing user experience and product quality. Not only do smartphones, portable electronics and headphones require excellent tactile experience, but their supporting wires also have soft-touch and abrasion-resistant requirements. Si-TPV, due to its excellent performance characteristics, makes a big splash in the application of 3C electronic supporting wire field.

Si-TPV is not only soft to the touch like silk, but also has excellent durability. Its resistance to abrasion and tearing makes it ideal for frequent use, and Si-TPV's elasticity ensures a long-lasting soft touch. In addition, Si-TPV is recyclable and environmentally friendly, in line with the growing emphasis on sustainable manufacturing practices.

What are the advantages of Si-TPV Soft Elastic Material (Thermoplastic Elastomers) in wires?

01 Excellent long-lasting skin-friendly and smooth feel(Extremely Silky Feel Material without Additional Coating)

Si-TPV Elastomeric Materials utilizes Soft Slip Coating Technology to provide a long-lasting, soft, silky feel that is similar to that of high quality silicone rubber and provides a pleasant user experience without the need for secondary processing. This feature makes Si-TPV material has a wide range of application prospects in the field of 3C electronic supporting wires.

02 Dirt-resistant and easy to clean (Dirt-resistant Thermoplastic Elastomers)

Si-TPV Elastomeric Materials, with good dirt-resistant and easy to clean characteristics, in daily life process stains and dust and other easy to be cleaned up, so that the wire is always clean and beautiful.

03 Environmental protection and recyclability (Sustainable Elastomeric Materials)

Si-TPV Elastomeric Materials meet the requirements of environmental protection, does not contain plasticizers and other harmful substances, and can be recycled, in line with the concept of sustainable development, is a kind of Environmentally Friendly Thermoplastic Elastomers. this feature makes it in the field of 3C electronic supporting wire This feature makes it has a wide range of application potential in the field of 3C electronic supporting wires.

04 Excellent Abrasion and Scratch Resistance, Sweat Resistance and Water Resistance (TPU with Improved Frictional Properties)

Si-TPV Elastomeric Materials that is Tpu For Improved Handling, compared with traditional TPU materials, its wear and scratch resistance is better, can make the wire to avoid being scratched or worn out in daily use, to extend the service life. At the same time, it has good resistance to sweat, can resist the erosion of sweat, and is a Skin Safety Comfortable Waterproof Material, can ensure the stable operation of the cable in a variety of environmental conditions at the same time harmless to human skin.

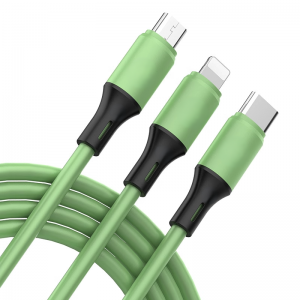

05 Diverse colors and appearance

Si-TPV Elastomeric Materials has good coloring performance, high color saturation, can be adjusted according to the needs of the color, making the appearance of the wire more beautiful and easy to identify.

06 High elasticity and rebound shrinkage

Si-TPV Elastomeric Materials has high elasticity and rebound shrinkage similar to rubber, which makes it able to maintain good flexibility and durability when used as the outer skin of 3C electronic supporting wires, effectively resisting external physical damage.

07 Excellent weather resistance

As Si-TPV Elastomeric Materials has excellent weather resistance, it has excellent effect in resisting the erosion of UV and other natural factors, so that the wire can maintain long-term stable operation when used in a variety of environments, and can meet the needs of complex and changing scenes of use.

Si-TPV will be an innovative solution for Elastomeric Materials in Consumer Electronics to improve the aesthetics, comfort and durability of 3C electronic ancillary cables, including headphone cables, charging cables, data cables and more.

For additional details, please visit www.si-tpv.com or reach out to amy.wang@silike.cn via email.