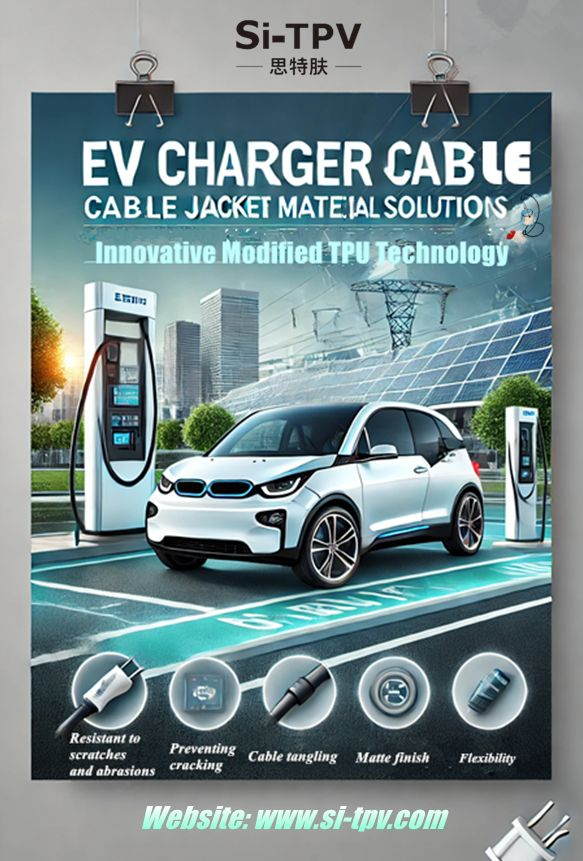

The rise of electric vehicles (EVs) brings forth a new era of sustainable transportation, with fast-charging infrastructure playing a crucial role in supporting widespread EV adoption. Fast-charging piles, vital components of this infrastructure, demand robust and reliable cables to connect them to EVs. Thermoplastic polyurethane (TPU) has become a go-to material for EV Charging cables due to its flexibility and wear resistance. However, real-world challenges such as durability, surface finish, and user experience often hinder its full potential. How do I troubleshoot common issues with EV charging cables?

Don't panic! If you're an EV charging cable manufacturer facing these challenges, here’s a proven solution for TPU . But before diving into solutions for EV charging TPU cables, let's first review the common issues associated with them.

1. Durability Concerns:

TPU cables face environmental and mechanical challenges, including:

- Environmental Exposure: Extreme temperatures, UV radiation, and ozone cause material degradation, cracking, and reduced lifespan.

- Mechanical Wear: Bending, stretching, and friction lead to abrasions and wear, compromising the cable’s integrity.

2. Surface and Aesthetics Issues:

- Visible Damage: Frequent handling causes scratches and marks, affecting both appearance and functionality.

- Poor Tactile Experience: Rough or damaged surfaces reduce user satisfaction.

3. Thermal Stability Issues:

- Heat Deformation: High temperatures from fast charging can soften or deform TPU, affecting performance and safety.

- Performance Degradation: Overheating may cause insulation breakdown, risking electrical faults.

4. User Convenience Problems:

- Tangling and Knotting: TPU cables are prone to tangling, making storage and use inconvenient.

- Stiffness vs. Flexibility: Some cables are too stiff, others too flexible, both impacting ease of use.

5. Chemical Resistance Limitations:

- Chemical Damage: Exposure to oils, cleaners, or chemicals can degrade TPU or cause staining, affecting both performance and appearance.

Strategies to Solve EV Charging TPU Cable Challenges: Ways to Optimize TPU Formulation

To overcome the challenges faced by TPU cables in EV charging applications, optimizing the TPU formulation is essential. By improving durability, flexibility, and wear resistance, TPU cables can retain their structural integrity under frequent bending and exposure to harsh weather conditions. Here’s how to enhance the performance of these cables.

Si-TPV 3100-60A is a dynamic vulcanized thermoplastic silicone-based elastomer, engineered through a specialized compatible technology that ensures silicone rubber is evenly dispersed in TPU as 2-3 micron particles under a microscope. This unique combination offers the strength, toughness, and abrasion resistance typical of thermoplastic elastomers while incorporating the desirable properties of silicone, such as softness, a silky feel, and resistance to UV light and chemicals. Importantly, these materials are recyclable and can be reused in traditional manufacturing processes.

As a highly efficient plastic additive and polymer modifier from SILIKE, Si-TPV 3100-60A is specifically designed to improve the performance of TPU cables. Its advanced formulation not only enhances durability and flexibility but also delivers a flawless matte finish, making it an ideal solution for EV charging cables, industrial cables, and a wide range of consumer electronics applications.

Key Benefits of Si-TPV 3100-60A for TPU Cables

Superior Durability: Si-TPV 3100-60A Enhances abrasion and scratch resistance, significantly reducing wear and tear from frequent use.

Flawless Matte Finish: Si-TPV 3100-60A Provides a consistent, high-quality matte surface that is both visually appealing and durable while enhancing color vibrancy for bolder designs.

Enhanced Flexibility and Strength: Si-TPV 3100-60A Balances structural integrity with flexibility, minimizing tangling and kinking.

Soft Ergonomic Feel: Si-TPV 3100-60A creates a soft, sandblasted texture that improves user comfort and handling.

Application Case: Optimizing TPU Formulation with Si-TPV 3100-60A

Adding 6% Si-TPV to TPU formulations improves surface smoothness, enhancing scratch and abrasion resistance. Increasing the percentage to over 10% results in a softer, more elastic material, producing resilient and efficient cables. Additionally, Si-TPV enhances the soft-touch feel and achieves a matte surface effect, further improving durability.

Proven Results: Successfully tested and validated across industries, including automotive and consumer electronics.

Innovative Design: Combines aesthetics, durability, and user comfort uniquely.

Sustainability: Supports the development of long-lasting, eco-friendly products.

Contact SILIKE to discover how our advanced Modified TPU Technology and Innovative Material Solutions can elevate your products TPU cable durability and surface quality enhancement.

If you’re looking for effective strategies to improve TPU formulations for enhanced cable performance and matte finish TPU cable, feel free to connect with us at amy.wang@silike.cn.