Visual representation of various overmolded parts, such as power tools, automotive parts, and consumer electronics with highlighted areas showcasing the soft-touch, enhanced design, and functional features.

What Are the Key Challenges in Overmolding?

Overmolding is a crucial process for enhancing product performance and user experience, but it comes with its own set of challenges. Common issues manufacturers face include:

Material Compatibility: Ensuring strong adhesion between the substrate and overmolded materials.

Deformation or Warping: Heat and pressure can cause materials to deform or warp during the molding process.

Durability Concerns: Overmolded parts must withstand harsh conditions like chemicals, temperature extremes, and mechanical stress.

Design Flexibility: Balancing performance with aesthetic flexibility can be tricky, especially in complex geometries.

Common Materials Used in Overmolding

Several materials are commonly used for overmolding, each offering different benefits depending on the application:

Thermoplastic Elastomers (TPE): TPEs provide flexibility, softness, and excellent tactile properties, making them ideal for products that require comfort and grip, such as handles and seals.

Thermoplastic Polyurethane (TPU): TPU offers good abrasion resistance, low friction, and high durability, often used for overmolding automotive parts, power tools, and medical devices.

Silicone Rubber: Known for its high thermal stability, flexibility, and biocompatibility, silicone is commonly used in medical and baby products.

Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS): Both materials are often used for hard, structural parts that need to be tough yet lightweight.

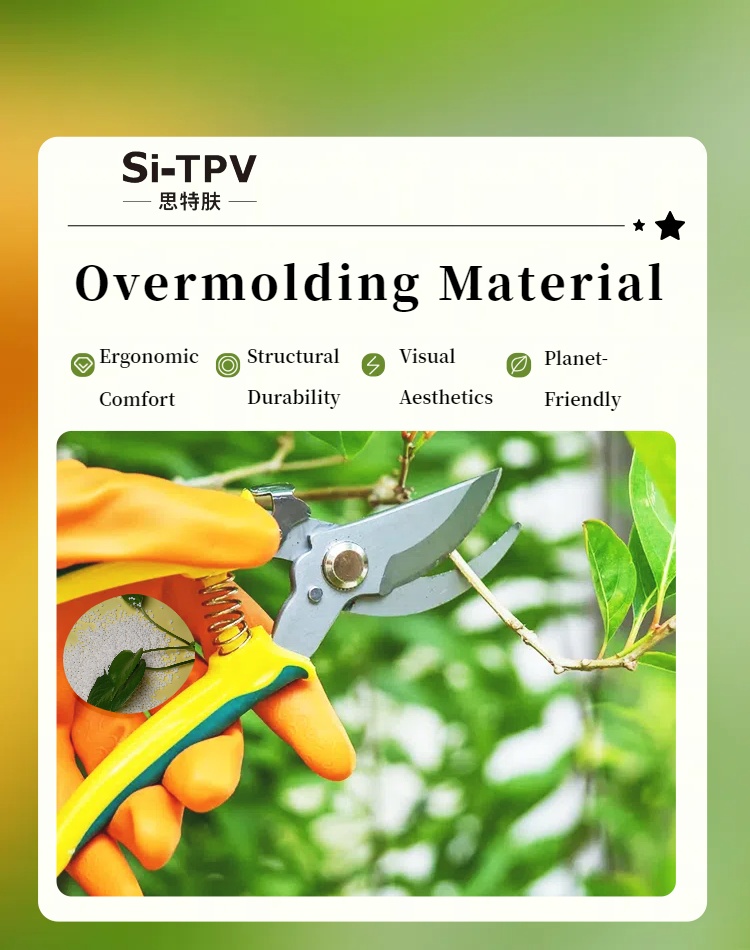

New Overmolding Material Solutions: Innovative Materials for Advanced Overmolding Applications

As manufacturers look for ways to improve performance and meet environmental standards, new overmolding materials are emerging to address existing challenges:

Si-TPV (Silicone Thermoplastic Vulcanizate): SILIKE's Si-TPV series products address the challenge of incompatibility between thermoplastic resin and silicone rubber through advanced compatibility and dynamic vulcanization technologies. This innovative process disperses fully vulcanized silicone rubber particles (1-3µm) uniformly within the thermoplastic resin, creating a unique sea-island structure. In this structure, the thermoplastic resin forms the continuous phase, while the silicone rubber acts as the dispersed phase, combining the best properties of both materials.

As a result, SILIKE's Si-TPV series Thermoplastic Vulcanizate Elastomers provide a soft touch and skin-friendly experience, making them the ideal choice for overmolding applications.

The Benefits of Si-TPV Overmolding Solution

Choosing the right overmolding material is critical to ensuring both performance and sustainability. Si-TPV Overmolding Materials solutions offer:

Improved Durability: Si-TPV Enhanced wear and tear resistance ensures longer-lasting products.

Better Environmental Compliance: Material like environmental protection and recyclability of thermoplastic Silicone-based elastomer(Si-TPV) for a circular economy meet the latest sustainability regulations.

Higher User Satisfaction: Compared to PVC, most soft TPUs and TPEs, Si-TPV Overmolding Materials have a unique silky, skin-friendly feel and are stain-resistant. They contain no plasticizers, are self-adhesive to hard plastics, and can be easily bonded to materials like PC, ABS, PC/ABS, TPU, PA6, and similar polar substrates, resulting in a pleasant tactile experience across diverse applications.

Design Flexibility: Si-TPV is a plasticizer-free thermoplastic elastomer that serves as a new overmolding material. It can handle complex geometries and help manufacturers design aesthetically pleasing products without compromising performance.

Whether you're designing sporting and leisure equipment, personal care products, power and hand tools, lawn and garden tools, toys, eyewear, cosmetic packaging, healthcare devices, smart wearable devices, portable electronics, handheld electronics, household appliances, or more,you need a material that combines safety, flexibility, and comfort. With Si-TPV overmolding solutions, these new overmolded materials offer a soft touch, skin-friendly feel, and non-toxic properties, making them the ideal solution for a wide range of applications. Contact SILIKE at amy.wang@silike.cn.

3.jpg)