Why Is Soft Overmolding on Nylon So Important?

Nylon, as an engineering plastic, is widely used in various applications due to its excellent mechanical properties. However, its rigid surface often leads to a poor tactile experience and potential skin abrasion during human contact. To address this, soft elastomers with Shore hardness ranging from 40A to 80A (typically 60A~70A) are overmolded onto nylon substrates, providing skin-friendly protection, enhanced tactile comfort, and greater design flexibility.

Traditional physical bonding methods (e.g., snap-fit designs, knurling, or threaded surfaces) for nylon overmolding suffer from inconsistent adhesion strength and limited design freedom. In contrast, chemical bonding leverages molecular affinity, polarity, or hydrogen bonding between materials, ensuring uniform adhesion across the interface and enabling complex geometries.

The Drawbacks of Using TPU for Nylon Overmolding

Thermoplastic Polyurethane (TPU) is widely used for overmolding onto nylon due to its wear resistance and good mechanical balance. It is often considered compatible with nylon due to their similar polarity. However, TPU often suffers from poor interfacial adhesion, leading to peeling or delamination, especially in high-stress or long-term use scenarios—ultimately compromising product quality and performance.

Solution: Introducing Si-TPV 3525- 65A, TPU alternative, the best elastomer for nylon overmolding

To address the limitations of TPU, Silike has developed Si-TPV 3525- 65A—a silicone-thermoplastic vulcanizate elastomer that maintains the desirable properties of TPU while significantly improving adhesion to nylon substrates.

This innovative soft overmolding Si-TPV thermoplastic elastomer material offers:

1. Excellent chemical bonding with PA6, PA12, and PA66

2. Durable, uniform overmolding interface

3. Soft-touch surface with enhanced user comfort

4. Outstanding mechanical durability, water, oil resistance, and cold flexibility

Superior Overmolding Performance of Si-TPV 3525- 65A on Nylon Substrates, A Comparative Study with TPU for Enhanced Bonding and Tactile Comfort!

Testing the Adhesion: Standardized Overmolding Evaluation

To compare bonding performance, Si-TPV and TPU were tested using a standardized overmolding procedure:

Nylon (PA6) substrates were injection-molded, then diagonally cut at 45° and polished with 120-grit sandpaper.

The treated substrates were reinserted into molds for overmolding under controlled temperature and pressure.

Tensile tests were conducted to evaluate interfacial bonding strength.

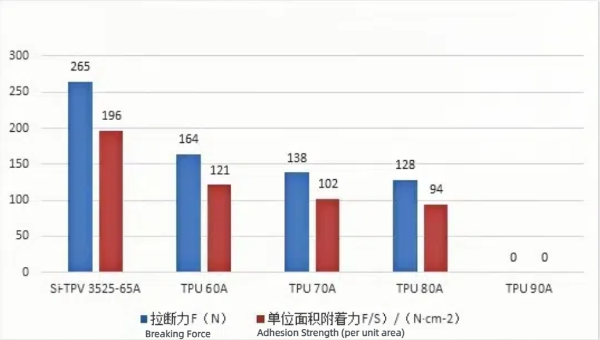

TPU vs. Si-TPV 3525- 65A on PA6: Tensile Force at Break & Adhesion Test Results

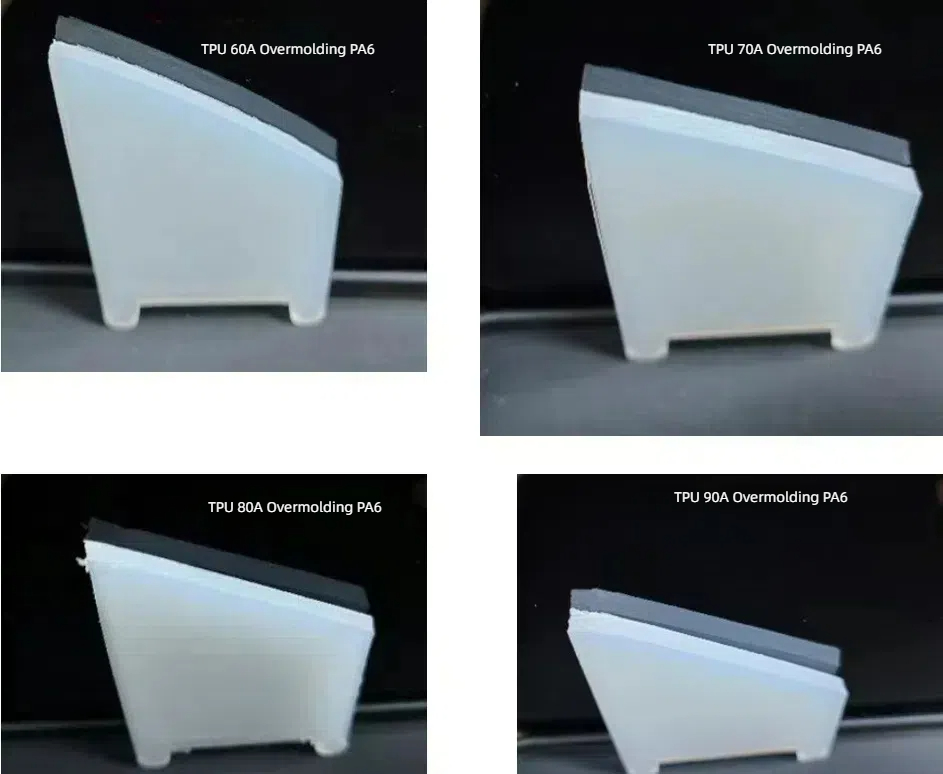

TPU Overmolding on PA Substrates :

As TPU hardness increased (60A to 90A), bonding strength to PA6 significantly dropped. At 90A, TPU failed to bond entirely.

Si-TPV 3525-65A Overmolding, TPU alternative for nylon overmolding:

Demonstrated strong and consistent bonding with PA6. Cross-sectional analysis revealed cohesive failure—Si-TPV remained attached to both sides of the interface, proving strong chemical bonding. In contrast, TPU interfaces showed minimal residue, indicating weak adhesion.

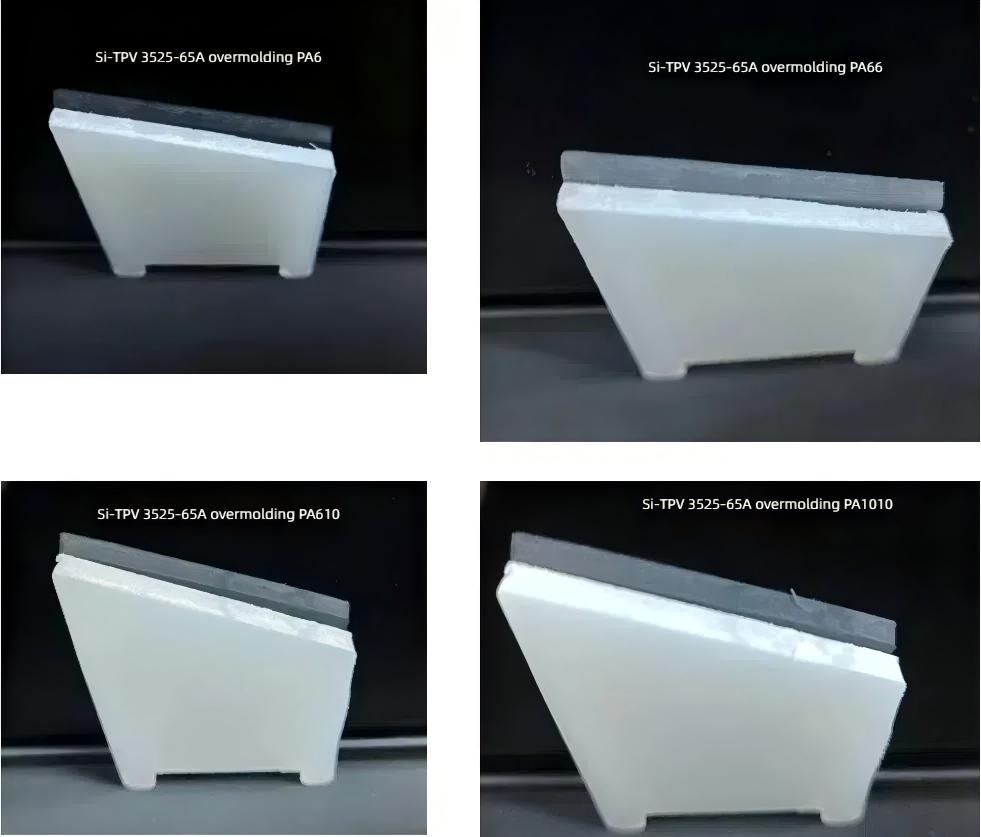

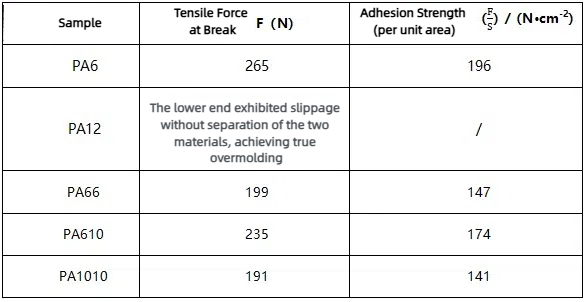

Soft-touch material Si-TPV 3525- 65A on all kind of Nylon Grades: Reliable Across PA6, PA12, PA66

Modified Silicone Elastomer 3525- 65A also achieved robust bonding across multiple nylon types.

Non-Sticky Thermoplastic Elastomer Si-TPV 3525- 65A on PA12, overmolding showed no visible separation during testing, confirming true cohesive bonding without interface failure.

Plasticizer-Free Elastomers Si-TPV 3525- 65A on PA66, the material maintained strong adhesion and structural integrity under load.

(Note: All Shore hardness values and test procedures align with international elastomer and adhesion testing standards.)

Goodbye TPU Peeling – Upgrade to Skin-Friendly, Soft-Touch Si-TPV for Durable Nylon Overmolding

Si-TPV 3525- 65A combines the mechanical resilience of TPU with the soft touch and chemical adhesion of silicone. It offers a breakthrough overmolding solution for nylon components used in consumer electronics, automotive interiors, and industrial tools.

By switching to Si-TPV, manufacturers can eliminate TPU peeling issues, extend product lifespan, deliver safety, aesthetics, and superior ergonomic performance.

Tel: +86-28-83625089 or +86-15108280799

Email: amy.wang@silike.cn

Website: www.si-tpv.com