Environmental problems are becoming more and more prominent as economic development, and achieving green chemistry is an urgent task nowadays.

Supercritical foam technology is a revolutionary new technology, the foaming agents used in supercritical foaming technology are usually supercritical carbon dioxide (ScCO2) and supercritical nitrogen (ScN2), both of which are used without environmental burden.

In footwear applications, Supercritical Foam Technology is revolutionizing the sneaker industry. This technology has allowed sneaker manufacturers to expand their range of materials beyond traditional TPU, TPE, and EVA. Now, they can also use materials such as PEBAX, ETPU, and other elastomers to create sneakers with superior cushioning and support, while lightweight, durable, comfortable, and environmentally friendly.

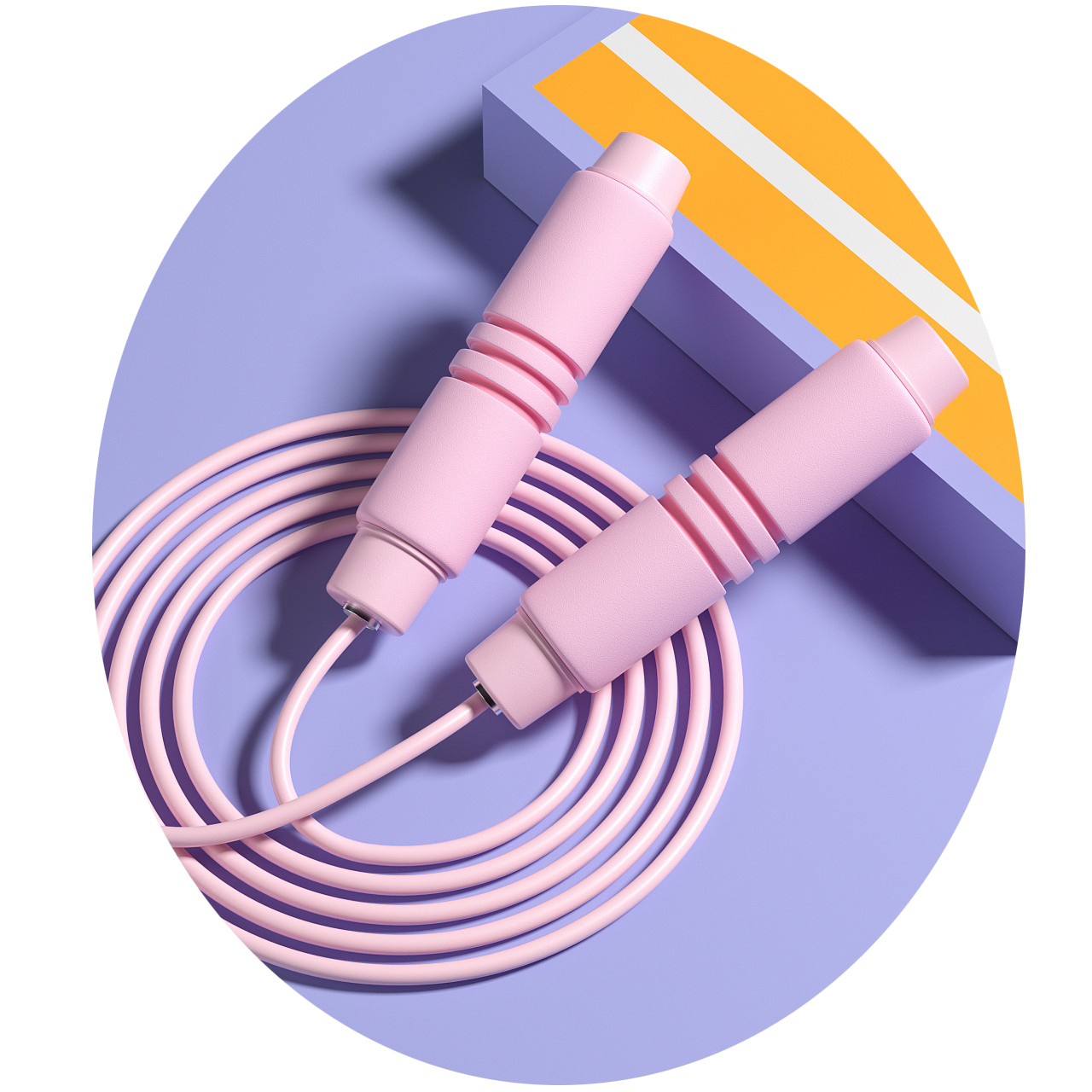

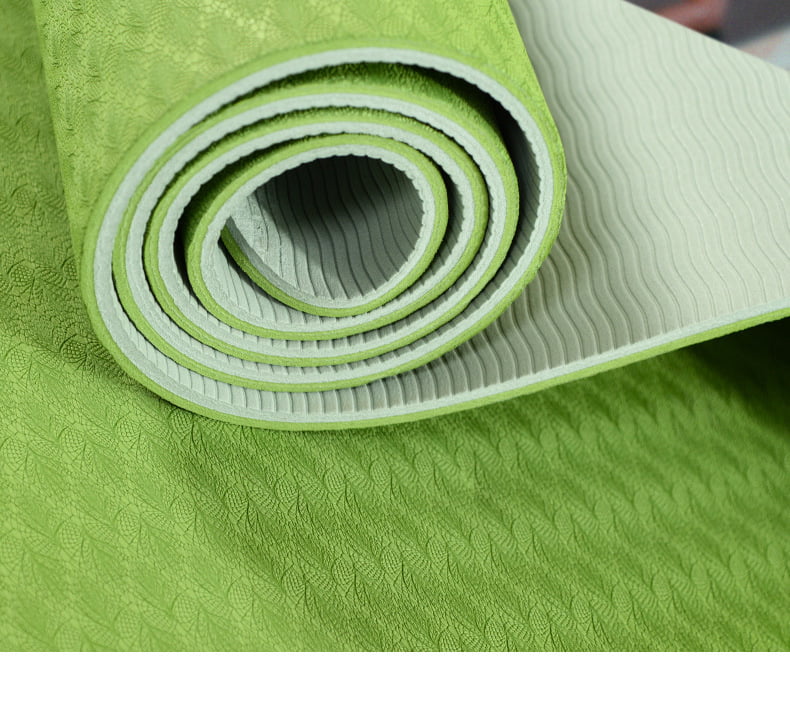

But with the use of supercritical foaming technology to produce EVA foam has revolutionized the way many industries use this material. This technology uses a combination of high pressure and temperature to create a foam that is lightweight, durable, and highly resistant to wear and tear. The process involves injecting a gas, such as carbon dioxide (ScCO2), into a liquid solution of EVA resin and other additives. The gas is then heated and pressurized until it reaches a supercritical state, which causes the gas to expand rapidly and form tiny bubbles. These bubbles are then trapped in the liquid solution, creating a foam that has superior properties compared to traditional foams. It is faster, lighter, stronger, and more durable, making it an ideal choice for a variety of applications. For example, from footwear provides cushioning and support for the feet to sanitary products, sports leisure products, floor/yoga mats, toys, packaging, medical devices, protective equipment, water non-slip products, photovoltaic panels, and more... It is also used in automotive and aerospace applications to provide insulation and soundproofing.

Sustainable Material Technologies for Innovations made of EVA foam!

However, he application of supercritical foaming technology to produce EVA materials requires attention to the issue of cross-linking. EVA molecular chains are linear and require a cross-linked structure to lock in the gas. Although it is already in production in footwear and some fields, it has not been applied on a large scale. the biggest problem of supercritical foaming is that the finished product rate is too low, less than 50%, thus restricting the development of supercritical foaming.

EVA was blended with 100% recyclable Si-TPV reshaping EVA foaming technology, This EVA foam technology helps drive sneakers in a more comfortable and sustainable direction. which not only can achieve low density and high resilience but also has excellent wear resistance, reduced thermal shrinkage rate, uniform color, high finished product rate, easy operation, and low cost, Compare to supercritical foaming.

As more industries begin to adopt this Soft EVA Foam Modifier Si-TPV blended with EVA technology, we can expect to see even more innovative uses for this revolutionary new material. Newness isn't limited to the ultra-light soft elastic sneaker industry.

If you are looking for Flexible Soft EVA Foam material Solutions, Modifier reduces the compression of EVA foaming, Chemical foaming technology for lightweight EVA foam, Soft EVA Foam Modifier or Solutions for supercritical foaming.

Please contact us, to learn more.

Email: amy.wang@silike.cn