In the dynamic world of dental care innovation, the electric toothbrush has become a staple for those seeking efficient and effective oral hygiene. A crucial component of these toothbrushes is the grip handle, traditionally made from engineering plastics such as ABS or PC/ABS. To enhance user experience, these handles are often coated with soft rubber, typically TPE, TPU, or silicone. While this method improves the feel and appeal of the toothbrush, it comes with complexities such as bonding issues and susceptibility to hydrolysis.

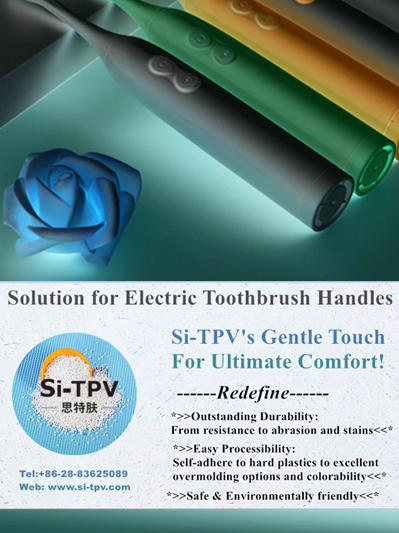

Enter Si-TPV (dynamic vulcanizate thermoplastic Silicone-based elastomers), a revolutionary material that is transforming the landscape of electric toothbrush grip handles. Si-TPV offers a seamless injection molding solution on engineering plastics, eliminating the need for cumbersome bonding processes and ensuring continuous, efficient production.

The Si-TPV Advantage:

Streamlined Manufacturing Process:

Unlike traditional methods involving the bonding of silicone or other soft materials with engineering plastics, Si-TPV simplifies the process by enabling direct injection molding. This not only streamlines production but also eliminates the complexity associated with glue bonding.

Continuous Production Efficiency:

Si-TPV's compatibility with injection molding allows for continuous production without compromising quality. This efficiency is a game-changer for manufacturers, ensuring a steady supply of electric toothbrush grip handles without interruptions.

Aesthetic Appeal and Unique Soft-Touch:

Si-TPV injection-molded handles retain their aesthetic appeal, providing a visually pleasing and functional product. The unique soft-touch characteristic of Si-TPV enhances the user experience, offering a comfortable and enjoyable grip during every use.

Stain-Resistant for Long-Lasting Beauty:

Si-TPV's resistance to staining ensures that the electric toothbrush grip handle maintains its pristine appearance over time. Users can enjoy both the functional benefits and the aesthetic appeal without concerns about discoloration or degradation.

Enhanced Durability and Bonding Strength:

Si-TPV provides a robust binding force under weak acid/weak alkaline conditions, such as those encountered with toothpaste water. The result is a grip handle that maintains its integrity, with significantly reduced risks of peeling off even in the most challenging environments.

Resilience Against Hydrolysis:

Practical tests have shown that Si-TPV resists hydrolysis under the influence of toothpaste water, mouthwash, or face cleaning products. This resilience ensures that the soft and hard components of the grip handle stay securely bonded, extending the lifespan of the toothbrush.

Revolutionizing Design: The Innovations of Soft Over-Molded Material

What's even more unique, Si-TPV also can be a soft over-molding material, it can bond with the substrate that endures the end-use environment. Such as excellent bonding to polycarbonate, ABS, PC/ABS, TPU, and similar polar substrates, It can provide a soft feel and/or non-slip grip surface for improved product features or performance.

When using Si-TPV the design and development of handles for personal care handheld products, not only appear to simply enhance the aesthetically pleasing of a device, adding a contrasting color or texture. Especially, Si-TPV overmolding’s lightweight functionality also elevates ergonomics, deadens vibration, and improves a device’s grip and feel. By this means the comfort rating is also increased compared to stiff handle interface materials such as plastic. As well as to provides additional protection from wear and tear which makes it an ideal solution for personal care handheld products, that need to withstand heavy use and abuse in a variety of environments. Si-TPV material also has excellent resistance to oil and grease which helps keep the personal care handheld products clean and functioning properly over time.

Additionally, Si-TPV is more cost-effective than traditional material, allowing manufacturers to produce more products in less time. It is an attractive option to create custom products that meet their specific needs while still providing superior performance in a variety of applications.

For more information regarding specific over-molding Si-TPVs and their corresponding substrate materials, please feel contact us!