TPU is a versatile material known for its hardness and elasticity, making it popular in various applications. However, traditional TPU faces challenges in meeting the specific performance demands of industries such as automotive, consumer goods, and medical devices. These challenges include inadequate surface quality, high hardness levels limiting flexibility, and a lack of desirable tactile properties, which can impact user experience and product longevity.

◆Solutions: Modified TPU Technology

The modification of TPU surfaces is crucial for developing materials that can optimize performance in specific applications. Understanding TPU hardness and elasticity is key. TPU hardness refers to the material’s resistance to indentation or deformation under pressure, while elasticity refers to its ability to deform under stress and return to its original shape upon stress removal.

In recent years, the incorporation of silicone additives into TPU formulations has gained attention for achieving desired modifications. Silicone additives play a vital role in improving the processing characteristics and surface quality of TPU without detrimentally affecting the bulk properties. This occurs due to silicone molecules’ compatibility with the TPU matrix, acting as a softening agent and lubricant within the TPU structure. This allows for easier chain movement and decreased intermolecular forces, resulting in a softer and more flexible TPU with reduced hardness values.

Additionally, silicone additives act as processing aids, reducing friction and enabling smoother melt flow. This facilitates easier processing and extrusion of TPU, enhancing productivity and reducing manufacturing costs.

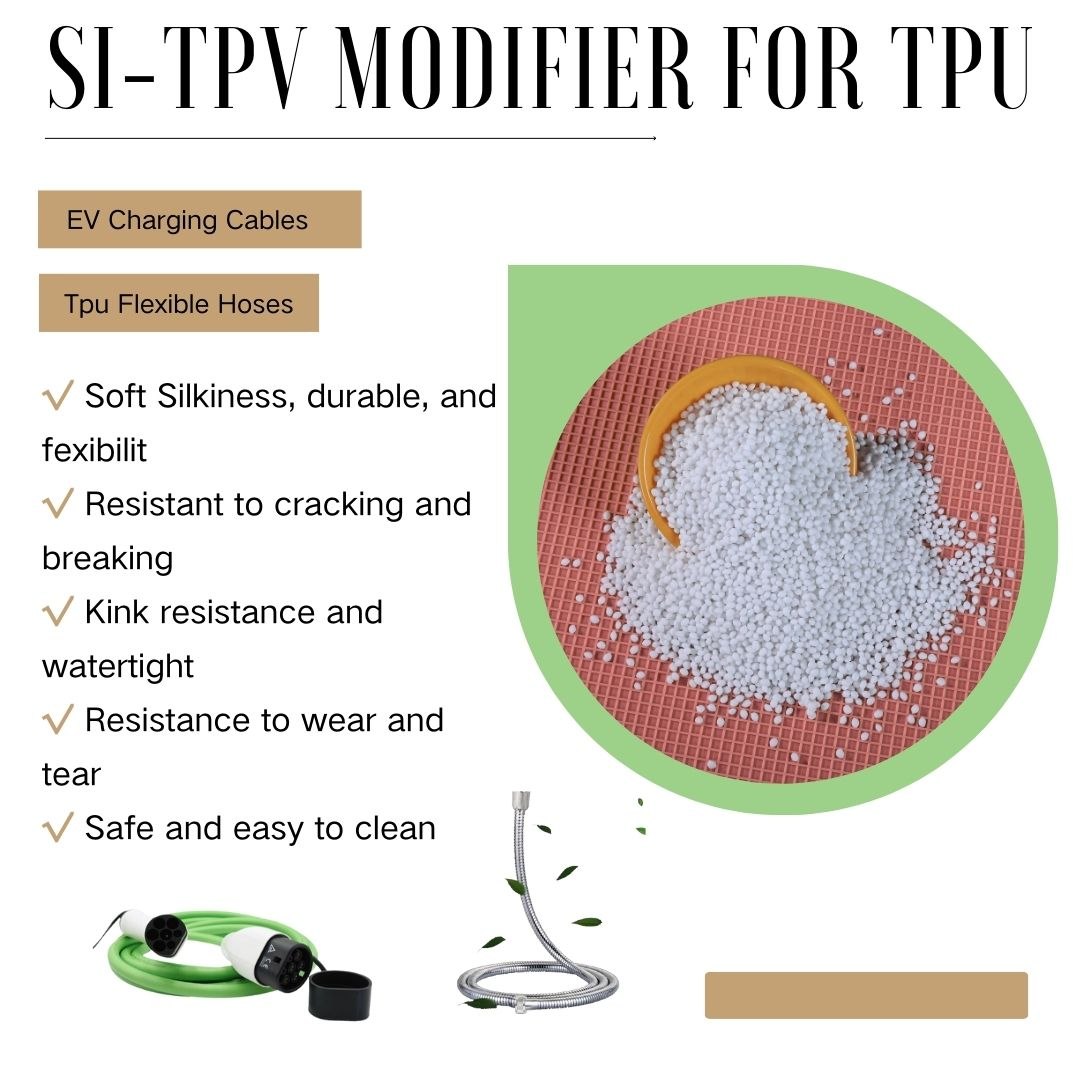

Innovative Plastic Additive and Polymer Modifier Solutions: Si-TPV Modifier For Tpu

Adding Si-TPV to thermoplastic polyurethane formulations allows manufacturers to achieve the ideal Modification For Tpu needed for a specific application, resulting in increased user satisfaction, enhanced product aesthetics, and improved productivity.

Key Benefits of Si-TPV in TPU:

1. Feel Modifier/Surface Modification For Tpu:Enhances long-term smoothness and tactile feel, while reducing flow marks and surface roughness.

2. Softer TPU:Allows for softer and more flexible TPU without compromising mechanical properties. For example, adding 20% Si-TPV 3100-65A to 85A TPU can reduce hardness to 79.2A.

3. It has better resistance to aging, yellowing and staining, and also has a matte effect to improve the aesthetics of the finished product, and Si-TPV is a Tpu Material Eco Friendly, 100% recyclable, does not contain DMF, and is harmless to the environment and the human body.

4. Unlike conventional silicone additives or modifiers, Si-TPV disperses finely throughout the TPU matrix, minimizing migration issues and ensuring consistent performance.

To explore effective strategies for improving TPU formulations from SILIKE, please contact us at amy.wang@silike.cn.