Detail

Material is the material means to realize the product, the carrier of technology and function, and the intermediary of communication between people and products. For massage products, material innovation is mainly the use of new materials, that is, new materials at the right time, suitable for massage equipment new product development. Application of materials science and technology new results of traditional products will present a new appearance image, give people a comfortable visual feeling and tactile feeling, to achieve better service function for people.

Key Benefits

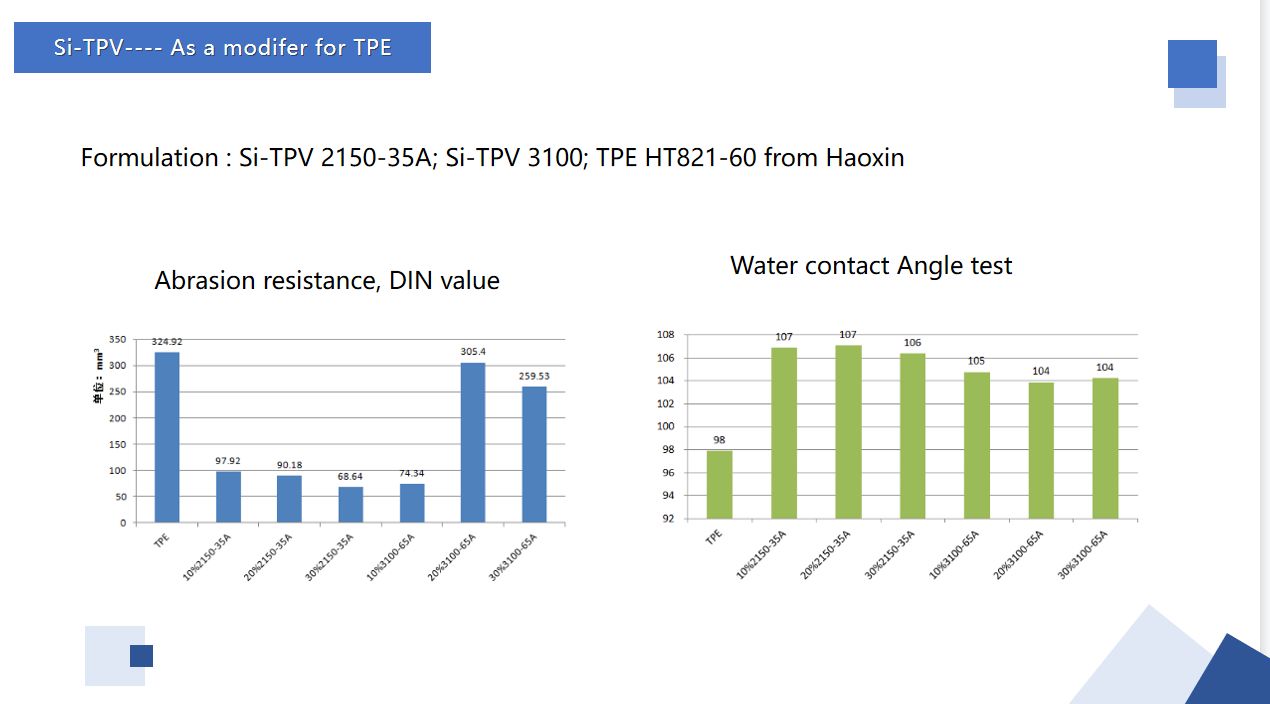

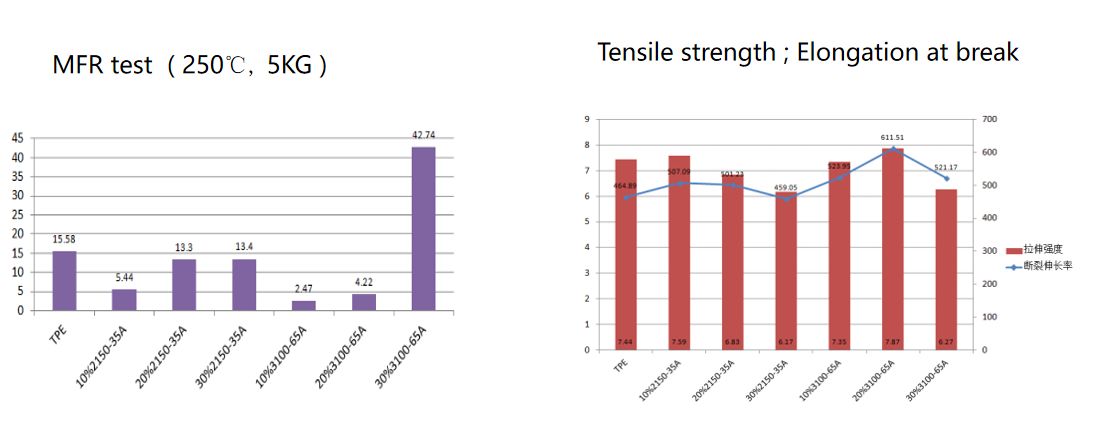

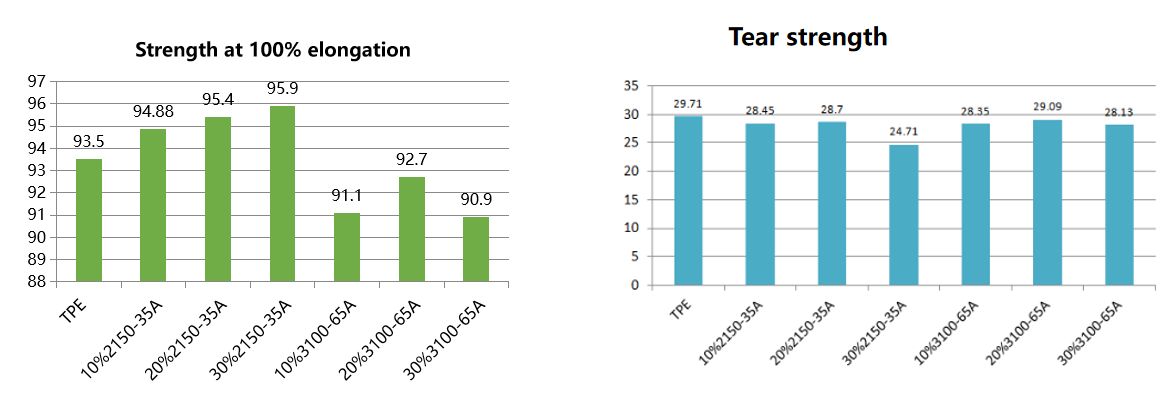

- In TPE

- 1. Abrasion resistance

- 2. Stain resistance with a smaller water contact angle

- 3. Reduce hardness

- 4. Almost no influence on mechanical properties with our Si-TPV 2150 series

- 5. Excellent haptics, dry silky touch, no blooming after long-term use

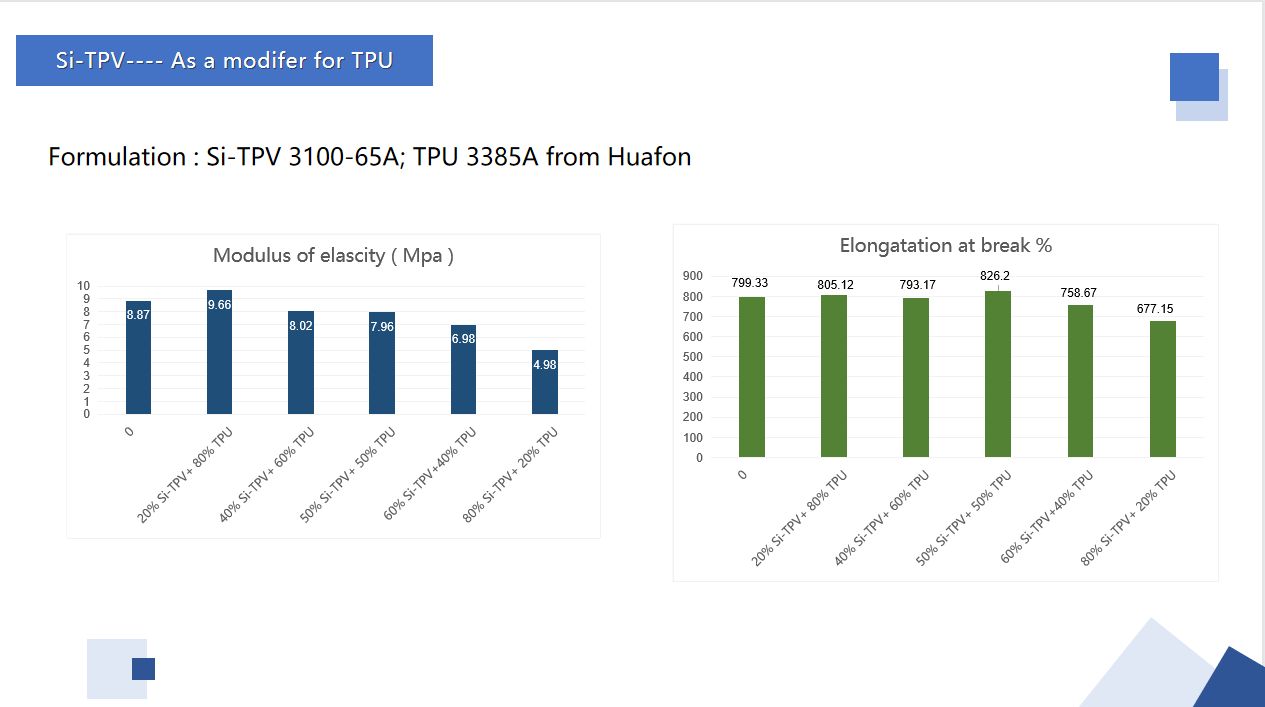

- In TPU

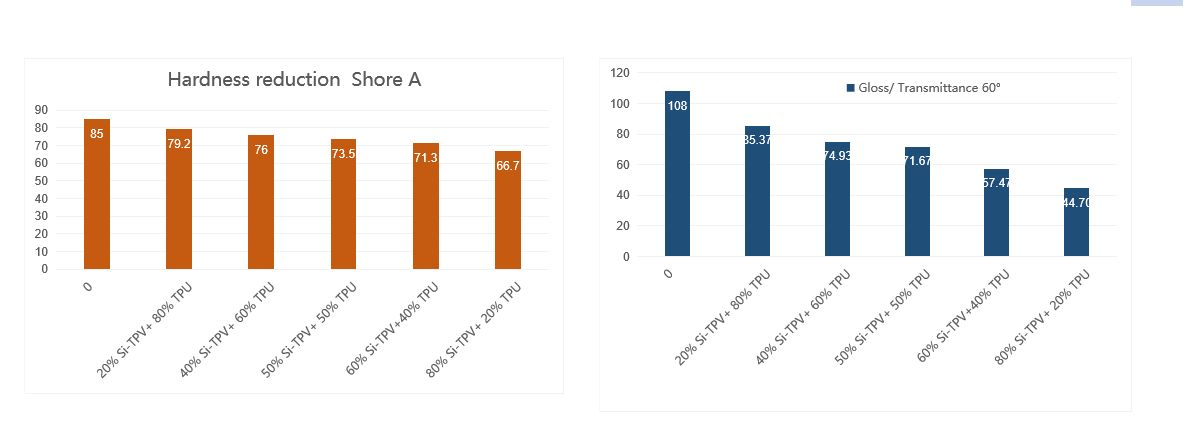

- 1. Hardness reduction

- 2. Excellent haptics, dry silky touch, no blooming after long-term use

- 3. Provide the final TPU product with a matt effect surface

- 4. Slightly affect Mechanical properties if the addition of over 20%

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations

Si-TPV as a modifer & process additive Guide

Si-TPV 2150 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for silky pleasant feel thermoplastic elastomers preparation.

Application

When selecting Si-TPV for overmolding applications, the type of substrate should be considered. Not all Si-TPVs will bond to all types of substrates. In addition to using Si-TPV overmolds on the head of a massager, it is a good idea to use Si-TPV overmolds on the body of the device or on the buttons - anywhere there is skin contact, Si-TPV track TPE overmolds can make a difference. Specific applications can include shoulder and neck massagers, facial beauty massagers, head massagers, and so on.

Early non-mechanical massage equipment are wooden, some mechanical massage products massage head is also wooden. And now it is mostly changed to use silicone material as the covering material of the massage instrument. Compared with the wooden massage head, silicone is softer and more resistant to high temperature, but its skin-friendly surface touch needs to be followed by a coating treatment, which causes pressure on the environment, and long-term use will be affected by the coating off the touch.

Today, with the increasing abundance of materials and the continuous development of material technology, the selection and utilization of materials are becoming more and more important in product design. How do you choose a coating material that provides soft elasticity and a long-lasting skin-friendly, smooth feel?

Soft Solutions: Enhancing Comfort through Overmolding Innovations>>