Detail

Baby safety bedrails made of Si-TPV materials can effectively solve these problems. First of all, Si-TPV has excellent wear resistance and can resist the friction and impact of the baby on the bed rail, providing better safety protection. At the same time, the softness and elasticity of the Si-TPV material make the surface of the bed rail smoother, reducing the risk of injury to the baby.

Key Benefits

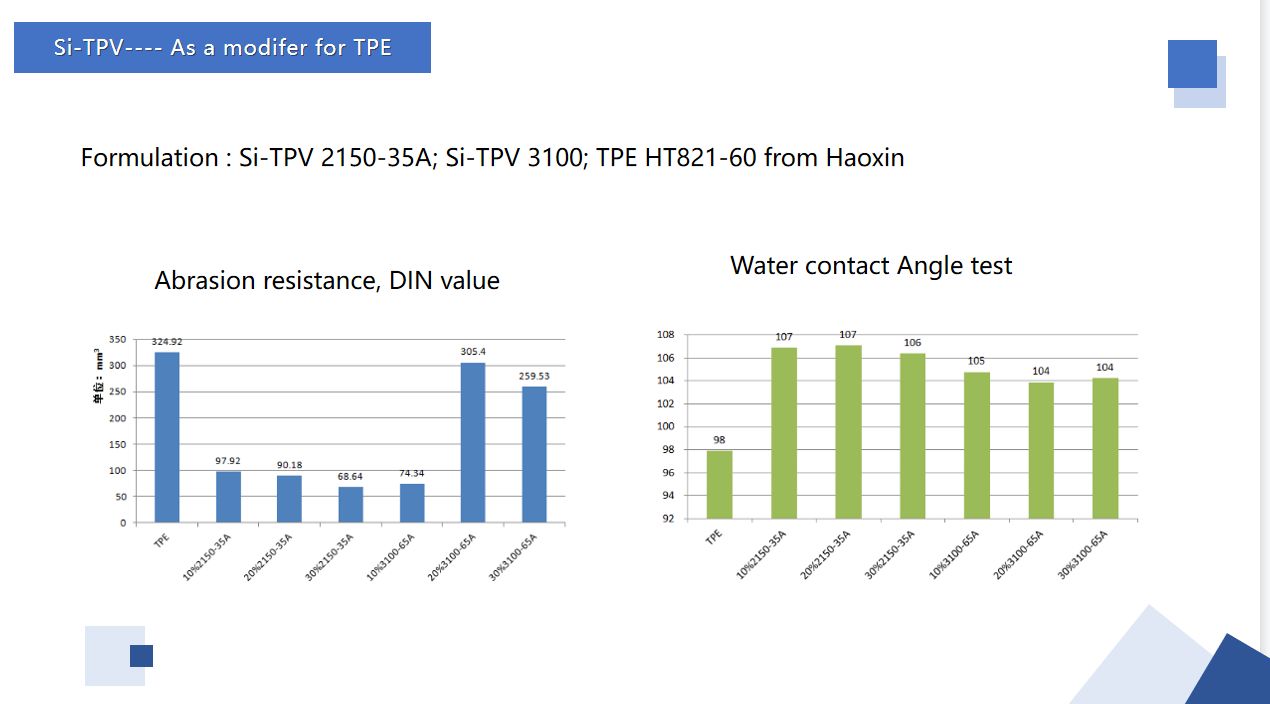

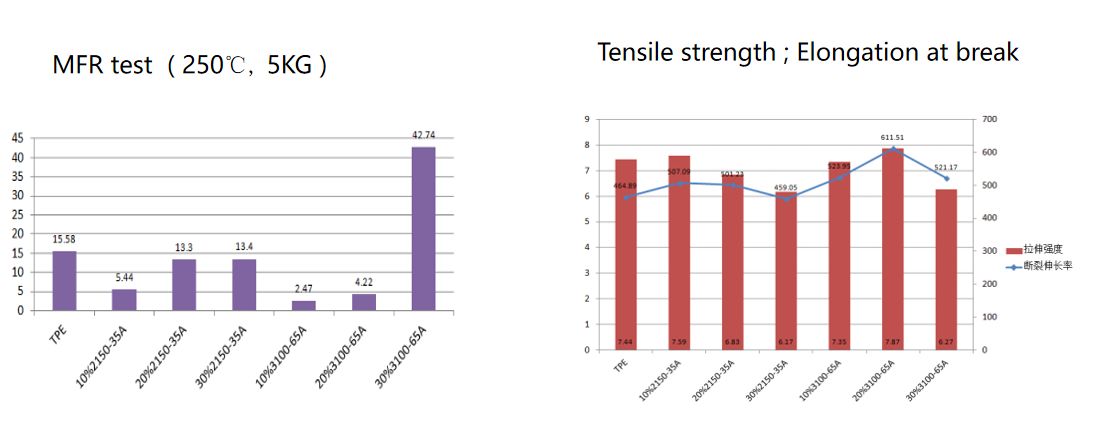

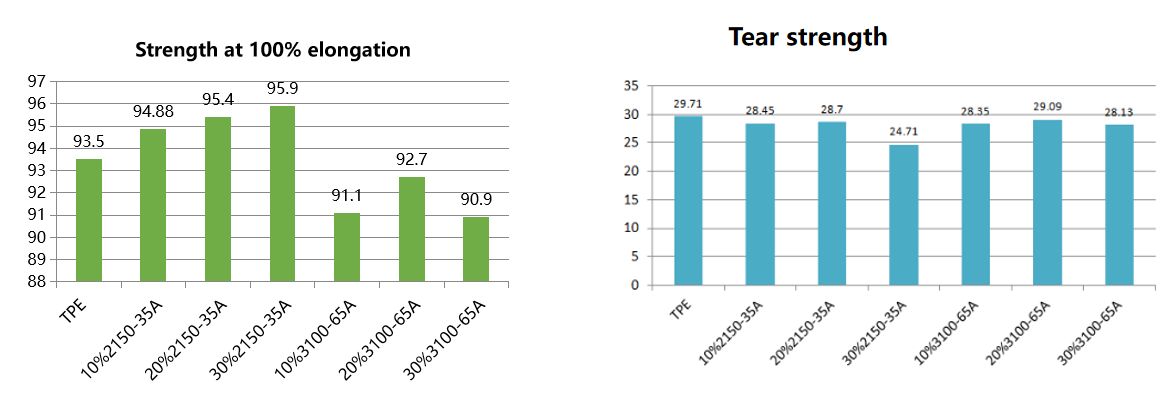

- In TPE

- 1. Abrasion resistance

- 2. Stain resistance with a smaller water contact angle

- 3. Reduce hardness

- 4. Almost no influence on mechanical properties with our Si-TPV 2150 series

- 5. Excellent haptics, dry silky touch, no blooming after long-term use

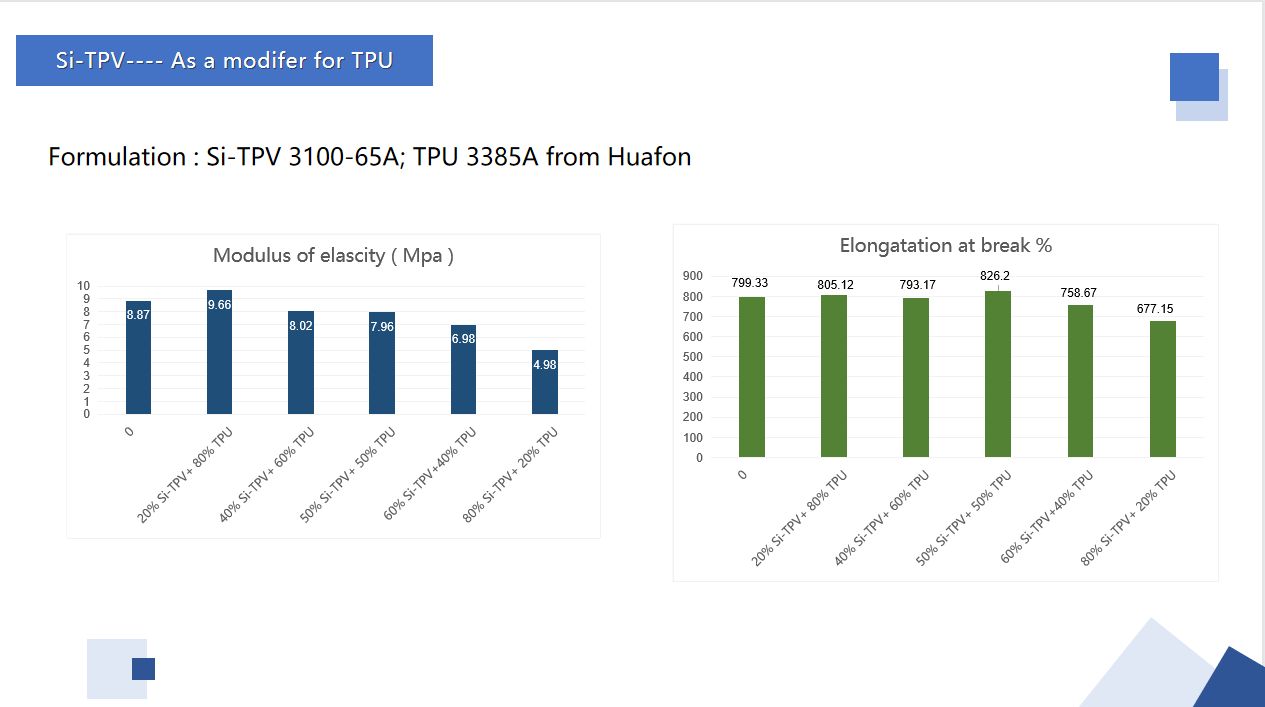

- In TPU

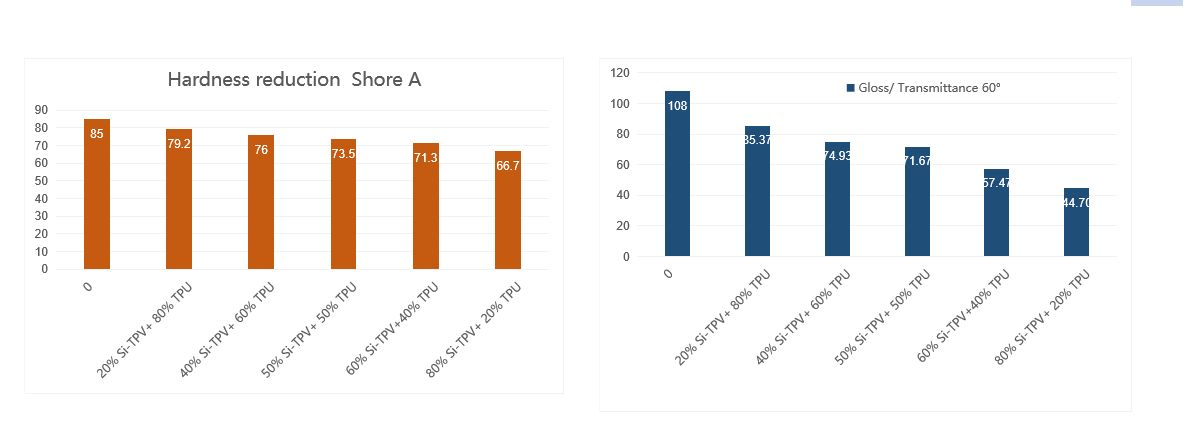

- 1. Hardness reduction

- 2. Excellent haptics, dry silky touch, no blooming after long-term use

- 3. Provide the final TPU product with a matt effect surface

- 4. Slightly affect Mechanical properties if the addition of over 20%

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations

Si-TPV as a modifer & process additive Guide

Si-TPV 2150 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, especially suitably used for silky pleasant feel thermoplastic elastomers preparation.

Application

Si-TPV as a new feel modifier & processing additive for thermoplastic elastomers or other polymers.It can be compounded to various elastomers, engineering, and general plastic; such as TPE, TPU, SEBS, PP, PE, COPE, and EVA to increase the flexibility, elasticity, and durability of these plastics. While a highlight of plastic products made with blends of TPU and the SI-TPV additive is a silky-soft surface with a dry feel. This is precisely the type of surface that end users expect of products that they frequently touch or wear. With these feature ,It has extended the range of their applications. In addition, The presence of Si-TPV Elastomeric Modifiers makes the process cost-effective as it reduces wastage due to expensive raw materials being discarded during processing.

Secondly, Si-TPV material has excellent water resistance and is easy to clean and disinfect. This is very important for crib rails as babies may spill food, secretions, etc. on the crib rails. Bed rails made of Si-TPV material can be cleaned more easily and have antibacterial properties to effectively prevent the growth of bacteria. In addition, Si-TPV material is an environmentally friendly material and does not contain harmful substances. This means that the baby safety bed rails made of Si-TPV will not release toxic substances during use and will not cause any harm to the baby’s health. To sum up, using Si-TPV materials to make baby safety bed rails can provide higher safety, ease of cleaning and comfort, giving parents greater peace of mind. Therefore, an application case of Si-TPV in the field of baby products is baby safety bed rails, which meet parents’ needs for baby safety through high-quality materials and design.