Detail

The SILIKE Si-TPV 2150 Series is a dynamic vulcanizate silicone-based elastomer, developed using advanced compatibility technology. This process disperses silicone rubber into SEBS as fine particles, ranging from 1 to 3 microns under a microscope. These unique materials combine the strength, toughness, and abrasion resistance of thermoplastic elastomers with the desirable properties of silicone, such as softness, a silky feel, and resistance to UV light and chemicals. Additionally, Si-TPV materials are recyclable and can be reused in traditional manufacturing processes.

Si-TPV can be used directly as a raw material, specifically designed for soft-touch over-molding applications in wearable electronics, protective cases for electronic devices, automotive components, high-end TPEs, and the TPE wire industries.

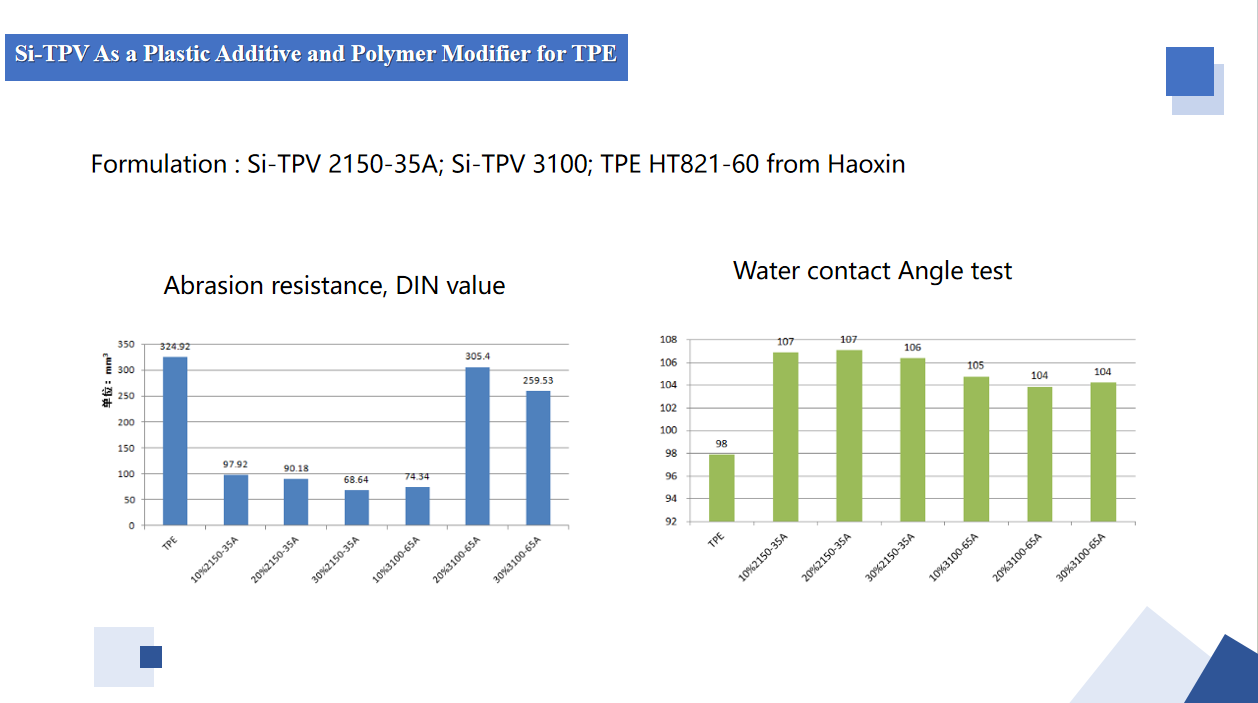

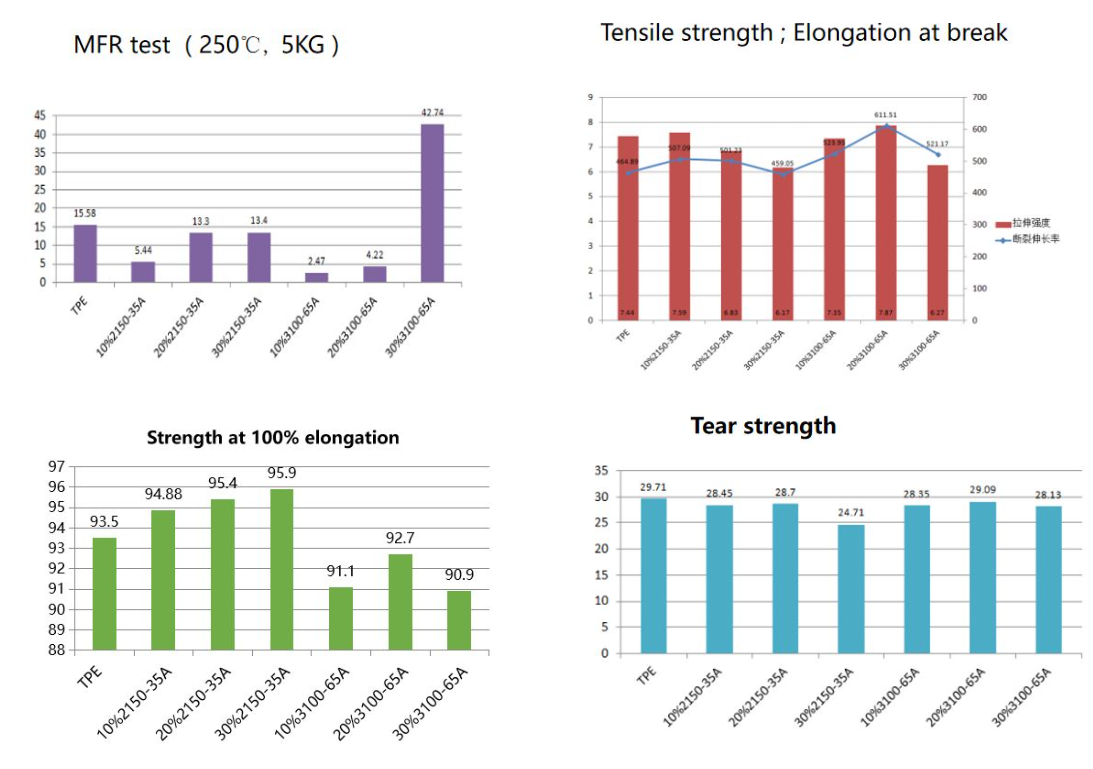

Beyond its direct use, Si-TPV can also serve as a polymer modifier and process additive for thermoplastic elastomers or other polymers. It enhances elasticity, improves processing, and boosts surface properties. When blended with TPE or TPU, Si-TPV provides long-lasting surface smoothness and a pleasant tactile feel, while also improving scratch and abrasion resistance. It reduces hardness without negatively affecting mechanical properties and offers better aging, yellowing, and stain resistance. It can also create a desirable matte finish on the surface.

Unlike conventional silicone additives, Si-TPV is supplied in pellet form and is processed like a thermoplastic. It disperses finely and homogeneously throughout the polymer matrix, with the copolymer becoming physically bound to the matrix. This eliminates the concern of migration or "blooming" issues, making Si-TPV an effective and innovative solution for achieving silky soft surfaces in thermoplastic elastomers or other polymers. and does not require additional processing or coating steps.

Key Benefits

- In TPE

- 1. Abrasion resistance

- 2. Stain resistance with a smaller water contact angle

- 3. Reduce hardness

- 4. Almost no influence on mechanical properties with our Si-TPV 2150 series

- 5. Excellent haptics, dry silky touch, no blooming after long-term use

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

Si-TPV plastic additive and polymer modifier Case Studies

Si-TPV 2150 series has the characteristics of a long-term skin-friendly soft touch, good stain resistance, no plasticizer and softener added, and no precipitation after long-term use, that serves as a plastic additive and polymer modifier, especially suitably used for silky pleasant feel thermoplastic elastomers preparation.

Comparing the Effects of Si-TPV Plastic Additive and Polymer Modifier on TPE Performance

Application

Si-TPV acts as an innovative feel modifier and processing additive for thermoplastic elastomers and other polymers. It can be compounded with various elastomers and engineering or general plastics, such as TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, and PVC. These solutions help enhance processing efficiency and improve the scratch and abrasion resistance performance of finished components.

A key advantage of products made with TPE and Si-TPV blends is the creation of a silky-soft surface non-tacky feel—precisely the tactile experience end users expect from items they frequently touch or wear. This unique feature broadens the range of potential applications for TPE elastomer materials across multiple industries. Furthermore, incorporating Si-TPV as a modifier enhances the flexibility, elasticity, and durability of the elastomer materials, while making the manufacturing process more cost-effective.

Solutions:

Struggling to Boost TPE Performance? Si-TPV Plastic Additives and polymer modifiers Provide the Answer

Introduction to TPEs

Thermoplastic elastomers (TPEs) are categorized by chemical composition, including Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), and Copolyamides (COPA). While polyurethanes and copolyesters may be over-engineered for some uses, more cost-effective options like TPE-S and TPE-V often offer a better fit for applications.

Conventional TPEs are physical blends of rubber and thermoplastics, but TPE-Vs differ by having rubber particles that are partially or fully cross-linked, improving their performance. TPE-Vs feature lower compression sets, better chemical and abrasion resistance, and higher temperature stability, making them ideal for replacing rubber in seals. In contrast, conventional TPEs provide greater formulation flexibility, higher tensile strength, elasticity, and colorability, making them suitable for products like consumer goods, electronics, and medical devices. They also bond well to rigid substrates like PC, ABS, HIPS, and Nylon, which is advantageous for soft-touch applications.

Challenges with TPEs

TPEs combine elasticity with mechanical strength and processability, making them highly versatile. Their elastic properties, such as compression set and elongation, come from the elastomer phase, while tensile and tear strength depend on the plastic component.

TPEs can be processed like conventional thermoplastics at elevated temperatures, where they enter the melt phase, allowing for efficient manufacturing using standard plastic processing equipment. Their operating temperature range is also notable, extending from very low temperatures—close to the glass transition point of the elastomer phase—to high temperatures nearing the melting point of the thermoplastic phase— adding to their versatility.

However, despite these advantages, several challenges persist in optimizing the performance of TPEs. One major issue is the difficulty in balancing elasticity with mechanical strength. Enhancing one property often comes at the cost of the other, making it challenging for manufacturers to develop TPE formulations that maintain a consistent balance of desired features. Additionally, TPEs are susceptible to surface damage such as scratches and marring, which can negatively impact both the appearance and functionality of products made from these materials.