Detail

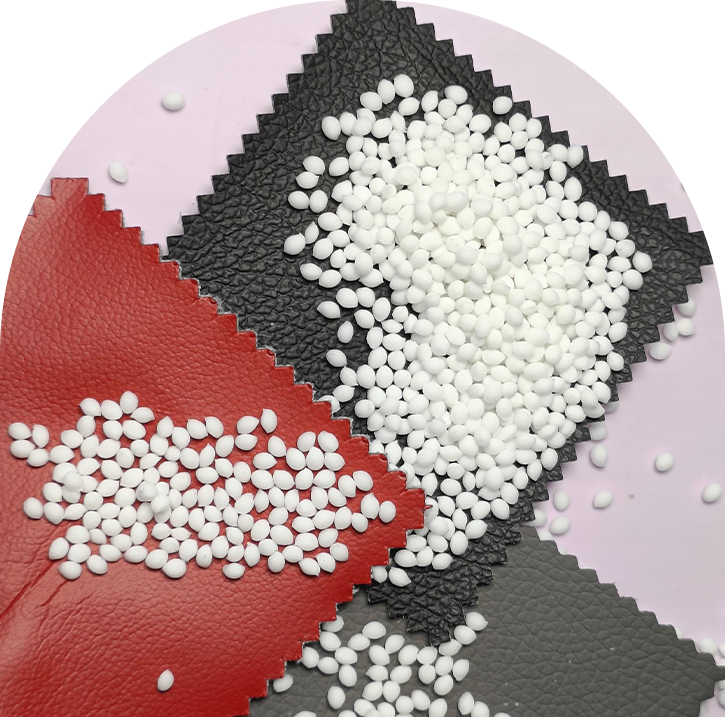

SILIKE Si-TPV series Thermoplastic Vulcanizate Elastomer is a soft touch, skin-friendly Thermoplastic Silicone Elastomers with excellent bonding to PP, PE, PC, ABS, PC/ABS, PA6, and similar polar substrates.

Si-TPV is a softness and flexibility of Elastomers developed for silky touch overmolding on wearable electronics, Handheld Electronics, phone cases, accessory cases, and earbuds for electronic devices, or slip Tacky Texture non-sticky elastomeric materials for watch bands.

Key Benefits

Durability Sustainability

-

Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

Si-TPV Overmolding Solutions

|

Overmolding recommendations |

||

|

Substrate Material |

Overmold Grades |

Typical Applications |

|

Polypropylene (PP) |

Sport Grips, Leisure Handles,Wearable Devices Knobs Personal Care- Toothbrushes, Razors, Pens, Power & Hand Tool Handles, Grips, Caster Wheels,Toys |

|

|

Polyethylene (PE) |

Gym Gear, Eyewear, Toothbrush Handles,Cosmetic Packaging |

|

|

Polycarbonate (PC) |

Sporting Goods, Wearable Wristbands, Handheld Electronics, Business Equipment Housings, Healthcare Devices, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Acrylonitrile Butadiene Styrene (ABS) |

Sports & Leisure equipment, Wearable Devices, Housewares, Toys, Portable Electronics, Grips, Handles, Knobs |

|

|

PC/ABS |

Sports Gear, Outdoor Equipment,Housewares, Toys, Portable Electronics, Grips, Handles, Knobs, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Standard and Modified Nylon 6, Nylon 6/6, Nylon 6,6,6 PA |

Fitness Goods, Protective Gear, Outdoor Hiking Trekking Equipments, Eyewear, Toothbrush Handles, Hardware, Lawn and Garden Tools, Power Tools |

|

Overmolding Techniques & Adhesion Requirements

SILIKE Si-TPV (Dynamic Vulcanizate Thermoplastic Silicone-based Elastomer) Series products can adhere to other materials through injection molding. Suitable for insert molding and or multiple material molding. Multiple material molding is otherwise known as Multi-shot injection molding, Two-Shot Molding, or 2K molding.

Si-TPV series have excellent adhesion to a variety of thermoplastics, from polypropylene and polyethylene to all kinds of engineering plastics.

When selecting a Si-TPV for soft touch overmolding application, the substrate type should be considered. Not all Si-TPVs will bond to all types of substrates.

For more information regarding specific Si-TPV overmolding and their corresponding substrate materials, please feel contact us now to learn more or request a sample to see the difference Si-TPVs can make for your brand.

Application

SILIKE Si-TPV (Dynamic Vulcanizate Thermoplastic Silicone-based Elastomer) Series.

products offer a uniquely silky and skin-friendly touch, with hardness ranging from Shore A 25 to 90. These Silicone-based Thermoplastic elastomers are ideal for enhancing the aesthetics, comfort, and fit of 3C electronic products, including handheld electronics and wearable devices. Whether it’s phone cases, wristbands, brackets, watch bands, earbuds, necklaces, or AR/VR accessories, Si-TPV provides a silky-smooth feel that elevates user experience.

Beyond aesthetics and comfort, Si-TPV also significantly improves scratch and abrasion resistance for various components such as housings, buttons, battery covers, and accessory cases of portable devices. This makes Si-TPV an excellent choice for consumer electronics, household products, homewares, and other appliances.

Solution:

3C Technology Material for Improved Safety, Aesthetics, and Comfort

Introduction to 3C Electronics

3C Electronic Products, also known as 3C products, 3C stands for “Computer, Communication and Consumer Electronics. These Products have become an essential part of our lives today due to their convenience and affordability. They provide us with a way to stay connected while still being able to enjoy entertainment on our terms.

As we know, the world of 3C electronic products is a rapidly changing one. With new technologies and products being released every day, Emerging 3C industry electronics product is mainly divided into intelligent wearable devices, AR/VR, UAV, and so on…

Especially, wearable devices have become increasingly popular in recent years for a variety of applications at home and at work, from fitness trackers to smartwatches, these devices are designed to make our lives easier and more efficient.

The Problem: Material Challenges in 3C Electronic Products

Although 3C Electronic Products offer a lot of convenience and benefits, they can also cause a lot of pain. The material used to make wearable devices can be uncomfortable and cause skin irritation or even rashes.

How to make 3C wearable devices so safe, reliable, and functional?

The answer lies in the materials used to create them.

Materials play a critical role in the design and functionality of wearable devices. These materials must be able to withstand extreme temperatures, humidity, and other environmental conditions while still providing function properly or reliably over time. they must also be safe, lightweight, flexible, and durable enough to withstand everyday wear and tear.

Common Materials Used for 3C Wearable Devices

Plastic: Plastic is lightweight and durable, making it an ideal choice for wearables. However, it can also be abrasive against the skin and cause irritation or rashes. This is especially true if the device is worn for long periods of time or if it’s not cleaned regularly.

Metal: Metal is often used for components such as sensors or buttons in wearable devices. Although it can provide a sleek and stylish appearance, metal may feel cold against the skin and cause discomfort during extended wear. It can also lead to skin irritation if not cleaned regularly.

Fabric and Leather: Some wearable devices are made from fabric or leather. These materials are generally more comfortable than plastic or metal but can still cause skin irritation if not cleaned regularly or if worn for long periods without washing or replacement. Additionally, fabric materials may not be as durable as plastic or metal, necessitating more frequent replacements.